We have a passion for unconventional solutions that bring your vision to life.

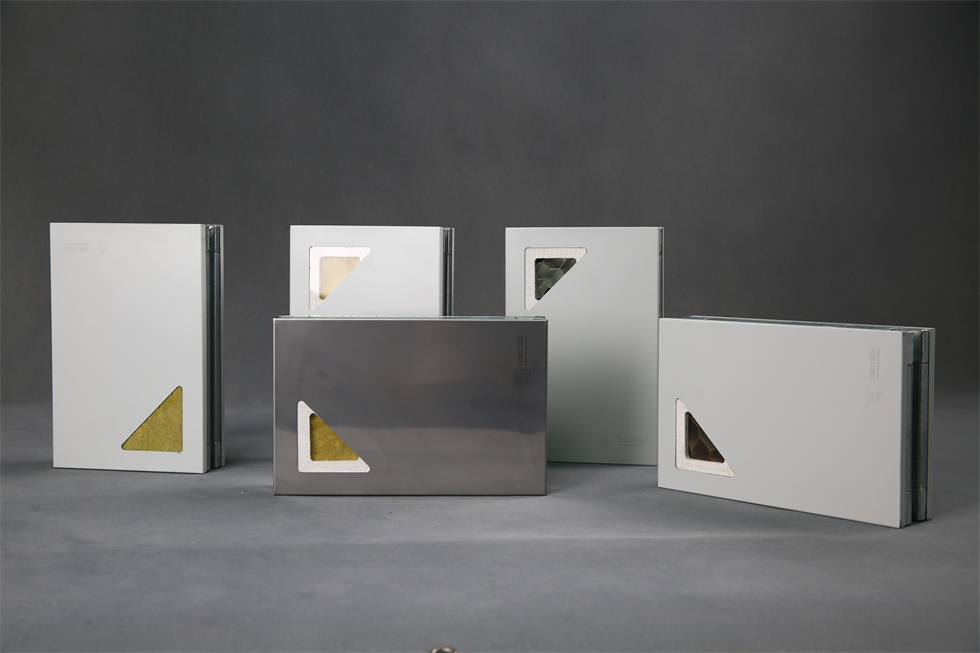

Cleanroom wall panels have high flatness, bright colors and beautiful appearance. They are favored by more and more customers because of their unique dust-proof, anti-static, anti-bacterial and many other superior properties.

Sandwich panels have become the main choice for clean room decoration. Sandwich wall panels are increasingly used in industrial electronics factories, pharmaceuticals, food, biology, aerospace, precision instrument manufacturing, scientific research and other places with stringent indoor environment requirements.

1. Ground leveling

Plastering is leveled and aligned according to the reference points on the wall. Compared with ordinary base plastering, the process of watering and moistening the wall is reduced. The mortar is mixed with a certain proportion of binder, and construction can be carried out as long as the dust and debris on the wall are cleaned. . Just use a 2m ruler to scrape the mortar flat, and it should not be calendered. The allowable deviations of the wall are: surface smoothness deviation ±2mm, vertical deviation of the facade ±2mm, and vertical deviation of the yin and yang angles ±2mm.

2. Ground grid laying out

Pop up the grid lines according to the large layout of the panels, leaving horizontal and vertical gaps between cleanroom panels, ensure that the elastic lines on the base wall are clear, horizontal and vertical.

3. Cut sandwich panel

According to the actual size of the on-site grid, the specific cutting size of the cleanroom wall panel will be provided. The cutting of sandwich panels can be completed by professional personnel in the factory or on the construction site. The cut cleanroom panel should have neat edges and corners, a diagonal deviation of less than 2mm, and a complete coating with no bulging or scratches.

4. Gluing the panel surface (gluing strips)

(1). Clean the stains and dust on the bonding surface of the cleanroom panel to ensure there is no oil, water stains and dust.

(2). Use a brush to apply silicone waterproofing agent on the section of the decorative panel at least twice.

(3). After the silicone waterproofing agent is dry, stick PE double-sided tape around the back of the cleanroom panel, and add two strips of PE double-sided tape in the middle of the short side to ensure the firmness of the bond.

(4). After attaching the double-sided tape, apply the building structural adhesive evenly on the middle part of the back of the sandwich panel using the spot-gluing method. The thickness of the building structural adhesive should exceed the thickness of the PE double-sided tape, generally not less than 6mm.

5. Paste the cleanroom wall panel

(1). The cleanroom panel is installed from bottom to top, with the positive corners first and then the negative corners.

(2). Remove the coating on the other side of the double-sided tape, and stick the sandwich panel on the wall according to the position of the grid lines. Generally, pressure line construction is used, and the flatness is controlled within 2mm (check with a 2m ruler).

(3). Temporarily use wooden keels (small pieces of nine-centimeter panel or slats) between the two cleanroom panels to fix the two panels so that the panels are fully adhered to the wall. They will be removed after the building structural adhesive has solidified.

6. Comprehensive inspection

After each section of installation is completed, the overall flatness, verticality, seam size and uniformity of the cleanroom panel surface should be checked, and appropriate adjustments should be made if necessary. After satisfactory results are achieved, proceed to the next step of installation.

7. Panel seam processing

(1). After all the cleanroom panels have been pasted, the overall quality and effect of the construction should be thoroughly checked again, and appropriate adjustments should be made if necessary. After satisfactory results are achieved, the wooden keels (nine-centimeter panels) used for temporary fixation should be removed.

(2). According to the size of the panel seam, select the appropriate caulking strip to fill the panel seam. It is required that the depth between the caulking strip and the panel surface is 3 to 5 mm.

(3). Stick masking paper (paper tape) along the panel seams according to the grid width requirements to prevent contamination of the panel surface, and then use a brush to apply silicone waterproofing agent at least twice on the section of the decorative panel.

(4). After the silicone waterproofing agent is dry, use a sealing gun to apply an even and appropriate amount of sealant into the seams of the panels, and then use a flat scraper to smooth the sealant. The required thickness of the sealant on the panels is 0.5 to 1mm. After gluing is completed, just pull off the paper tape.

8. Clean the panel surface

First clean the dust and dirt on the edge of the cleanroom panel, and then peel off the protective film. Be especially careful when cleaning the dirt on the surface of the sandwich. Do not scrub vigorously or scrape with sharp tools such as blades. Only solvents and clean water can be used for cleaning. After the sandwich wall panel construction is completed, the construction site should be cleaned after the joint sealant has solidified. All remaining materials are recycled and stored in categories. On-site garbage should be thoroughly cleaned and properly packaged before being transported to designated trash bins or centralized garbage processing centers.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.