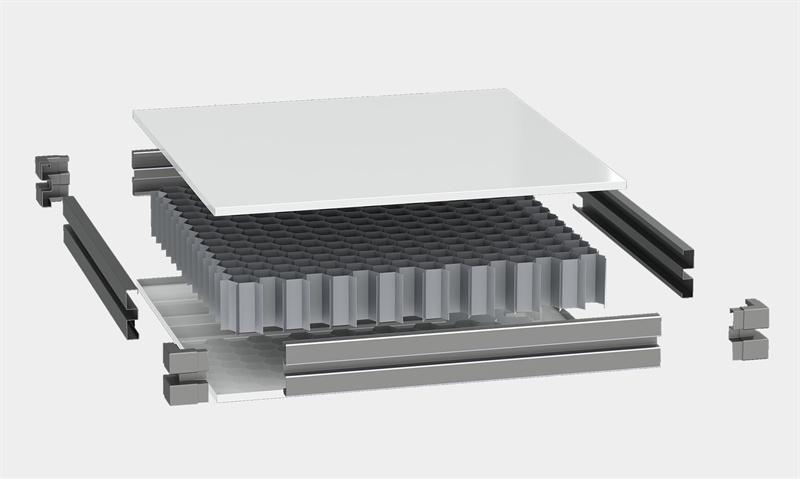

Cleanroom panel structure

The cleanroom panel consists of 5 parts: panel, core material, galvanized corner,frame, adhesive

1. Panel

The panel material is color-coated steel panel, stainless steel panel, film-coated panel, aluminum-magnesium-manganese alloy panel, etc. Currently, the most used panel material is color-coated panel, and the thickness of the cleanroom panel is between 0.4mm-0.6mm

2. Core material

Type | Advantage |

EPS | The panel is light in weight and easy to install |

Rockwool | Excellent fire performance Class A non-combustible |

Aluminum honeycomb | Lightweight, antistatic, good strength, B1 flame retardant |

Paper honeycomb | Light weight, high surface flatness, only carbonization but not burning |

MGO panel | Cooperating with other core materials can increase the fire protection time limit of four sides frame cleanroom panels |

Plaster panel | Cooperating with other core materials can increase the fire protection time limit of four sides frame cleanroom panels |

3. Frame and corner

Comparison of plastic corners and galvanized corners

| Plastic corners | Galvanized corners |

Appearance | Excellent | Good |

Melting point | 170 degrees | 1530 degrees |

4. Glue

The difference between one-component polyurethane glue and two-component polyurethane glue

| One-component polyurethane glue | Two-component polyurethane glue |

Element | NCO | NCO/OH |

Response type | React with water | Two-component reaction |

Response time | Can't control | Controllable according to temperature and humidity |