We have a passion for unconventional solutions that bring your vision to life.

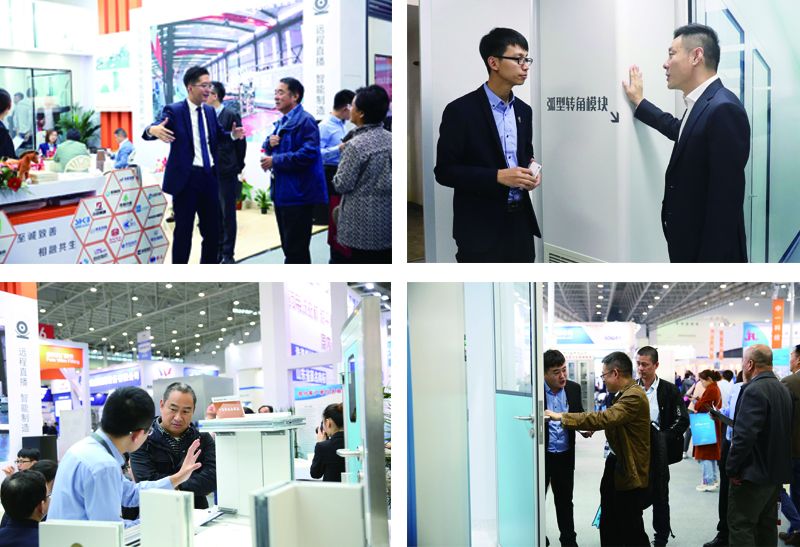

From November 5th to 7th, the 56th CIPM were held at Wuhan International Expo Center.

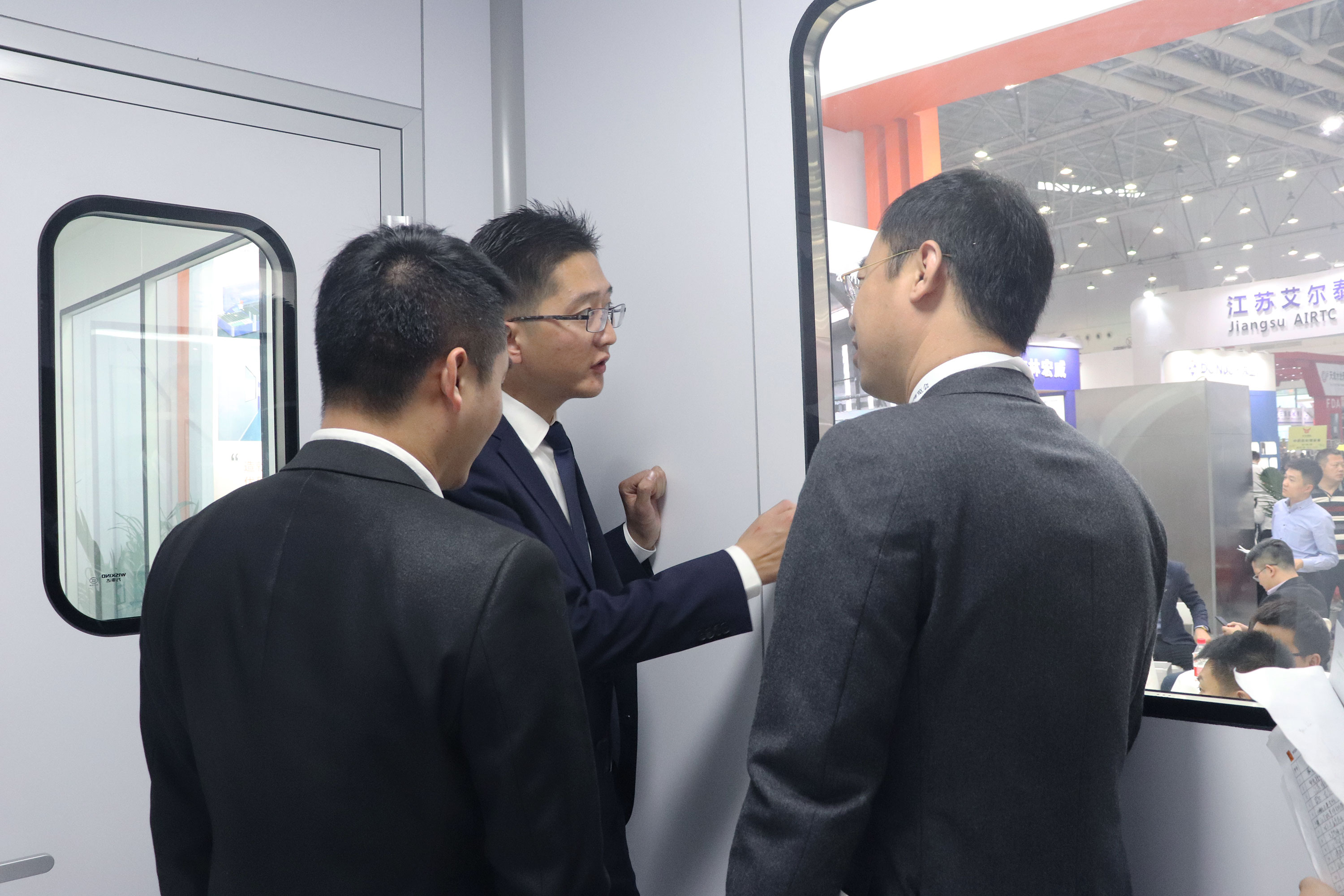

At the exhibition, Shandong Wish Wiskind clean Technology Co., Ltd. brought clean room doors and windows, new wall panels and the newly developed 100 HPL to inject new vitality into the modular clean room enclosure system, and gained industry experts and friends. Agree.

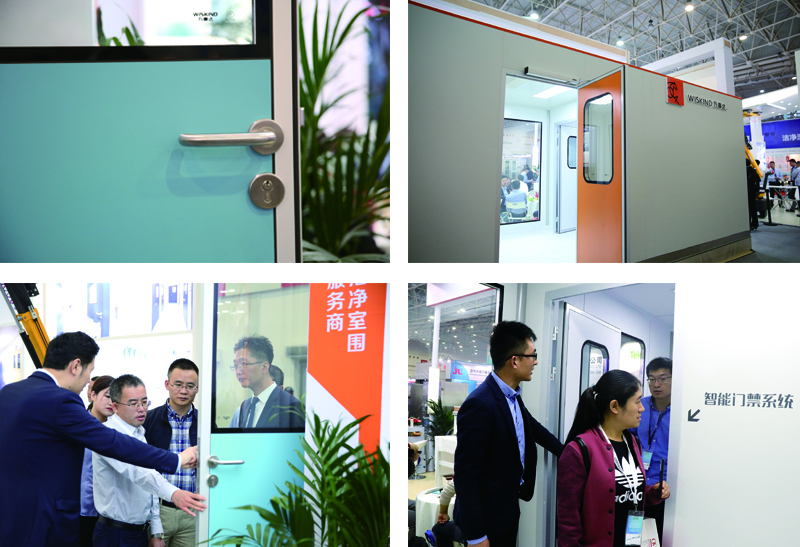

Clean doors and windows

Wiskind's clean doors and windows adopt the most advanced production equipment and technology in the world. From raw materials to door and window products, high-precision automated production processes occupy a leading position in the industry.

Wiskind clean doors and windows can be factory-scheduled, standardized production, and can be customized to meet the needs of different industries.

Clean technology intelligent access control system and intelligent induction cleanroom door stand on the customer's point of view to meet the needs of customers, making the access safer, more convenient and faster, attracting many customers to visit and guide, everyone has praised.

Wiskind's patented cleanroom windows are manufactured using industry-leading production processes to ensure that they are not foggy for fifteen years, so stay tuned.

HPL

The new wallboard has the characteristics of non-toxic, odorless, bacteria-resistant, abrasion-resistant, scratch-resistant, moisture-resistant and impact-resistant; the surface is non-porous and seamless, and has the advantages of dirt resistance, fading resistance, no dust generation, no dust accumulation and easy cleaning. It can withstand the high-end pharmaceutical VHP disinfection treatment and protect the customer's clean room.

100 thick hollow return air plate

The newly developed first-generation 100-thick hollow return wall panel can replace the return air column and the 100-thick hollow shrapnel wall in the dressing and unloading buffer room.

The return air module is processed in the factory, and the direct installation on site is more convenient and quick. In the later stage, it can be improved according to customer needs, making the product easy to clean and the air volume adjustable.

In addition to the new product debut, the live screen is the world's first automated production line of the clean-up board with independent intellectual property rights. The production line has an annual production capacity of more than 2 million square meters of sheet metal.

Technology makes every purification board the same quality.

The 56th CIPM lasted for three days and received more than 1,500 upstream and downstream customers from the domestic and international industry chain. It provided product information and customized advice and reached many cooperation intentions.

Wiskind has always adhered to the concept of customer value and focused on solutions for enclosures in clean environments.

Committed to become a professional clean room enclosure system service provider, modular clean room advocates and practitioners, as well as the largest domestic production capacity of clean board intelligent service providers.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.