We have a passion for unconventional solutions that bring your vision to life.

Food industry clean room (area) is an application of clean technology in raw material processing and deep processing production in the food industry. The clean room of the food industry not only controls the particles in the air, but also strictly controls the microorganisms in the air environment, technically preventing the cross-contamination of food by microorganisms. The most representative one is aseptic packaging. The aseptic packaging of food (such as soft-packed fresh juice, milk, etc.) is to complete the packaging process in a clean environment, which is greatly superior in maintaining food color, aroma, taste, and nutrition. It is used for general high-temperature sterilized canned food. In addition to aseptic packaging, air cleaning technology also has high applications in food brewing and fermentation.

The clean room (area) of the food industry refers to the clean room of the pharmaceutical industry, but is higher than the general clean room requirements. According to the original US Federal Standard FS 209B, which is now discontinued, it can be divided into 100 and 1000. , 10,000, 100,000, 3,000,000. According to the Chinese national standard GB-50073, which is in line with ISO-14644, there are 1-9 levels. The original 100, 1,000, 10,000, and 100,000 levels are Class 5, 6, 7, and 8 in the international standard ISO-14644 standard are replaced. The cleanliness of this type of clean room (area) is 1-8, of which 1-5, the air flow pattern is unidirectional Flow or mixed flow, wind speed 0.2-0.45m/s; 6-stage air flow pattern is non-unidirectional flow, air exchange frequency 50-60 times/h; 7-stage air flow pattern is non-unidirectional air flow, air exchange frequency 15- 25 times/h; the flow pattern of 8-9 levels is non-unidirectional flow, and the number of air changes is 10-15 times/h.

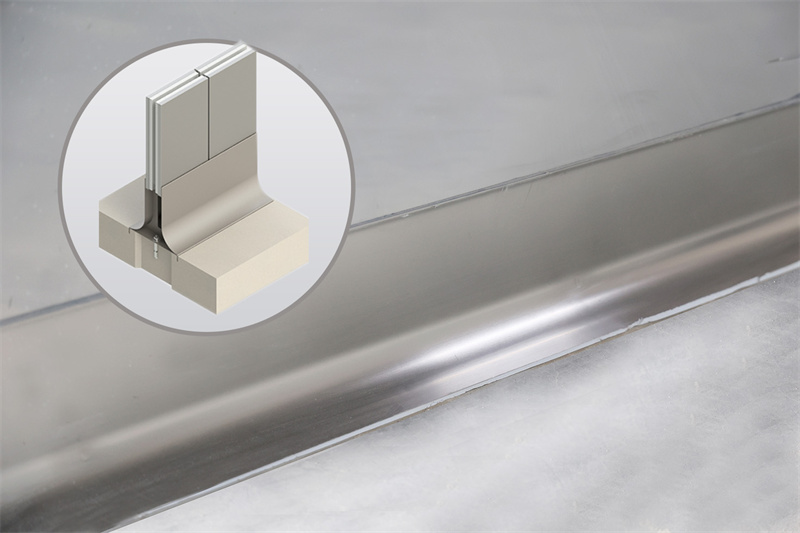

In order to ensure zero risk of food safety, it is necessary to uniformly complete the process of purchasing, storing, processing, packaging, retaining samples, transportation, cleaning and disinfection of dishes in the central kitchen. Therefore, in the process of construction, wall panels need to have the advantages of corrosion resistance, high temperature resistance and easy cleaning. At present, the central kitchen adopts stainless steel cleanroom panel.

The key point in the construction of food workshops is waterproofing. Since processing utensils need to be washed and disinfected and cooking frequently, it is necessary to do a good job of waterproofing the floor when installing the cleanroom panel and the ground. Wiskind has launched a brand new stainless steel for waterproofing. The waterproof node of the ground groove completely avoids the problem of corrosion and blistering of the board surface due to washing, which affects the service life of the plant.

Wiskind's concept of starting from customer value, focusing on clean room enclosure system solutions, further exerting its own advantages, better serving customers, and enhancing brand image.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.