We have a passion for unconventional solutions that bring your vision to life.

When we consider buying cleanroom panels, the first question we care about is: "How much is a square meter of cleanroom panels?" This question seems simple, but in fact, the price of cleanroom panels is affected by many factors. This article will answer this question for you from three aspects.

The main factors affecting the price of cleanroom panels: different panels and core materials

The price of cleanroom panels is mainly affected by the panels and core materials. Different panels and core materials have different costs, resulting in great differences in the price of cleanroom panels.

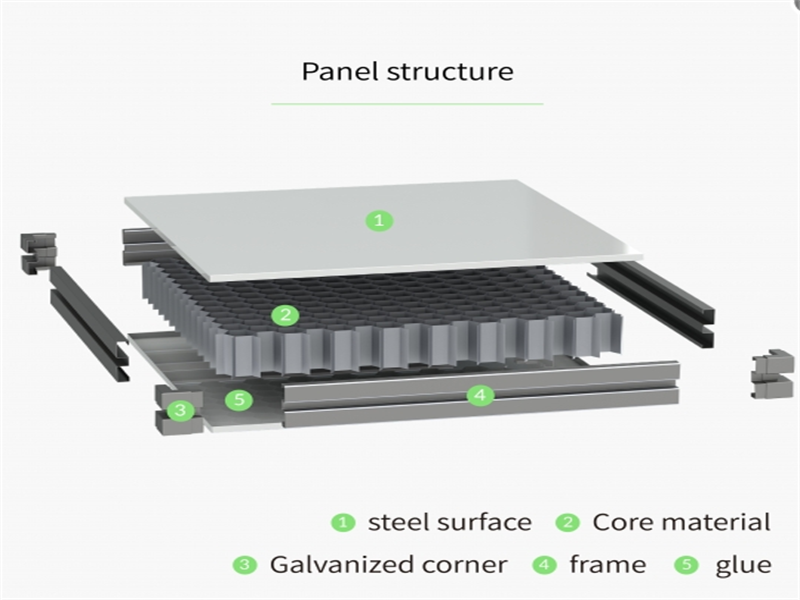

1. Panel material

The panel materials of the cleanroom panel mainly include color steel panel, stainless steel panel and melamine resin panel. The price of color steel panel is relatively low, but its corrosion resistance is poor, so it is not completely suitable for some areas where the controlled environment is relatively complicated. For example, the price of Endure® panel, which is commonly used in the environment with VHP disinfection in the pharmaceutical industry, is nearly twice as high as that of ordinary PE-coated color steel panels.

In the price fluctuation of cleanroom panel raw materials, the price fluctuation of panel materials is the largest, so even for cleanroom panels made of the same material, the price may vary at different times.

2. Core material

The core materials of the cleanroom panel mainly include rock wool, aluminum honeycomb, gypsum panel, MGO panel, etc. The type and quality of the core material are different, which will directly affect the performance and service life of the cleanroom panel, thus affecting the price.

Rock wool is a very common core material for cleanroom panels. It has excellent sound insulation, heat preservation, fire prevention and other properties, and at the same time the price is relatively low, so the price is more affordable. Aluminum honeycomb is a light-weight and high-strength material with excellent compression, bending, and shock resistance properties, and is suitable for occasions that require high strength of the panel. However, due to the high manufacturing cost, the price of the cleanroom panel is relatively high. Gypsum panel is an environmentally friendly, easy-to-process and easy-to-install material, suitable for some medium and low-grade clean rooms. However, due to its low density and insufficient strength, the price is relatively low. MGO panel is a very environmentally friendly, fireproof and other excellent materials, suitable for some occasions that require high cleanliness. However, due to the high manufacturing cost, the price is relatively high.

Technological innovation reduces costs: dSpace typesetting software independently developed by Wiskind

In order to reduce the non-standard rate and material loss, thereby reducing the total price of cleanroom panels, Wiskind independently developed the dSpace typesetting software. The dSpace typesetting software adopts advanced algorithms, which can automatically optimize the typesetting layout on the cleanroom panel production line, reduce the non-standard rate, and reduce material waste. Through the dSpace typesetting software, Wiskind can provide customers with more competitive prices for cleanroom panel.

There are many pain points in the traditional cleanroom panel typesetting method, which will affect the efficiency and quality in management, business and practical operation. Among them, a high proportion of non-standard boards is a common problem, which will affect production efficiency and yield. At the same time, the cost of communicating with upstream and downstream design teams is high, which affects collaboration efficiency and customer satisfaction. In addition, the entry threshold and learning cost of conventional BIM software are also high, which makes it difficult for clean engineering companies to promote the use of BIM software.

In order to solve these problems, Wiskind has developed dspace software, which is an intelligent design tool and design resource management platform for cleaning companies. This software implements the following functions:

First of all, dspace introduces a more convenient 3D forward design tool, which enables the cleanroom company to carry out design work more efficiently. This easy-to-use tool allows designers to design quickly and visually.

Secondly, dspace realizes the intelligent optimization of typesetting logic, reduces the non-standard rate, and improves the yield rate. This means that designers can design more accurately and reduce design errors, thereby improving production efficiency and yield. This can also reduce the cost of the business and increase profits.

Finally, dspace opened up the upstream and downstream design teams and linked customers to improve customer satisfaction and customer stickiness. This means that the cleanroom company can better communicate with customers, understand customer needs, and give timely feedback. This can also improve customer satisfaction, enhance customer stickiness, and help companies get more business.

At present, many engineering companies have used the dspace software and have received unanimous praise. This software enables cleanroom companies to carry out design work more efficiently, improve production efficiency and yield, and at the same time improve customer satisfaction and customer stickiness.

The Iron Triangle Team of Wiskind: Sales, Technology, Customer Service

On the premise of ensuring product quality, Wiskind also provides high-quality services, providing customers with a full range of services from purchase to delivery and installation. Wiskind's Iron Triangle team consists of sales, technology, and customer service, working together to provide customers with a hassle-free purchasing experience.

1. Sales team

Wiskind's sales team has rich industry experience and can help customers understand the price structure of cleanroom panels and provide customers with suitable cleanroom panel solutions.

2. Technical team

Wiskind's technical team has a professional technical background and can provide technical support to customers to ensure the quality and performance of cleanroom panels.

3. Customer service team

Wiskind's customer service team provides round-the-clock services to answer questions customers encounter during the purchase and installation process to ensure customer satisfaction.

Summary: The price of cleanroom panels is greatly affected by panel and core materials, and different material costs lead to price differences. Through the self-developed dSpace typesetting software, Wiskind Cleanroom reduces the non-standard rate and material loss, thereby reducing the total price. In addition, Wiskind's iron triangle team (sales, technology, customer service) provides customers with high-quality all-round services to ensure that customers can get the best cost performance when purchasing cleanroom panels.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.