We have a passion for unconventional solutions that bring your vision to life.

The enclosure materials used in clean rooms in China have experienced several stages from the very beginning, such as reinforced concrete, wood structure, steel-wood mixed structure and lightweight partition. Until this century began large-scale use of color steel plate. The metal composite steel cleanroom panel produced by Wiskind not only meets the requirements of GMP, but also improves the installation efficiency with its unique structure.

Painted steel cleanroom wall panel system

Color steel plate processing technology is becoming mature, the original clean room enclosure structure for reinforced concrete and other structures, the surface is coated with dust, smooth paint, such an environment can only be suitable for low-level clean room, it is difficult to meet the requirements of high-level clean room.

With the maturity of the industry, the materials and installation of clean room envelope structure have the characteristics of no dust emission, no dust accumulation and fast installation.With the unremitting efforts of professionals, the ship composite sandwich board, namely galvanized board filled with fire insulation material, has been introduced into the envelope structure of the clean workshop. Wiskind independently developed and produced manual sandwich color steel plates with various specifications and superior performance, which can meet the requirements of different clean rooms. In particular, our PVDP coated color steel plate can meet a broader range of clean room disinfection requirements, such as VHP disinfection.

Clean room color steel cleanroom panel installation construction should be adjusted keel installation and meet the corresponding requirements, site cleaning can be completed before.

Installation principle of wallboard: the installation direction should start from the corner or end, it is not recommended to start from the middle.

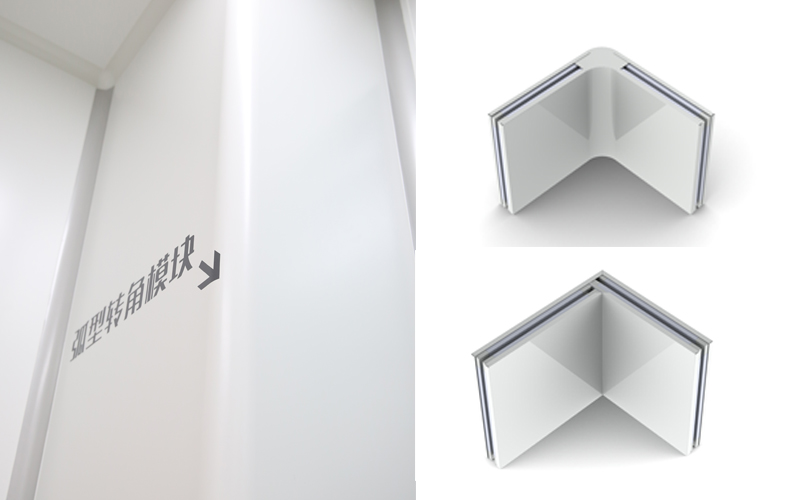

One Piece Aluminum Profile Cleanroom Corner Systems and wall panel installation

Fix the matching t-type aluminum into the bow-shaped groove of the wall panels on both sides, and then install the Angle, which is a whole long aluminum material, not split-together. Carefully adjust the joints between the corners and the wall panels. The gap between the corner and the ground is filled with matching aluminum alloy base (wiskind independently developed profiles). The installation of the first color steel plate should pay attention to the adjustment of keel will be fixed, not easily moved. Remove residual glue in bow groove before installation of wall panel. Insert the wallboard into the raised part of the adjusting keel, and connect the wallboard with matching aluminum profile.

Wall panels and roof panels are connected by top panels. Suction cup is used to control the seam of the plate so that it is evenly controlled at about 3mm. After installing 5 color steel plates, measure the vertical degree of the wall and the cumulative error of the total width of the wall board, and make appropriate adjustment and fixation.

Attention in the installation of color steel wall panel

The installation process of color steel plate wallboard used in supporting aluminum profile material connector, etc., are the company's own research and development and mold. The matching profiles can match all kinds of color steel plates produced by our company.Clean room color steel plate installation environment must be effectively controlled. Avoid construction work such as civil construction with too much dust on site. Effective isolation from this part of the job. The access of personnel, tools and materials shall be controlled.The fastening degree that adjusts keel is a foundation step that needs to take seriously in construction process.

Strong adjustment of the keel can effectively ensure the stability of the installation of color steel plate wallboard, is also the basis for the qualified installation of follow-up doors and Windows.Color plate wallboard installation process of wallboard and roof using top panel connection.

The top panel is fixed to the top panel (infrared control is adopted in the process to make the top panel correspond to the upper and lower parts of the adjusting keel accurately). This step ensures the verticality of the wall panels and provides a prerequisite for the subsequent installation of clean doors.Color plate wallboard installation process of the door head plate size should be noted. Determine the size of the door head plate according to the actual elevation of the ceiling. So that the roof and the door head board fit.The protection of finished products is particularly crucial in the installation process of color steel plate wallboard.

In the process of hoisting, soft materials should be added on both sides of the sling to protect it. It is strictly forbidden to drop or touch during transportation.The protective panel shall be used for anti-collision and anti-scratch protection immediately after the installation of the wall panel.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.