We have a passion for unconventional solutions that bring your vision to life.

There is nothing wrong with making sure your environment sparks with a high functioning shield that keeps impurities away. Pharmaceutical and biotech companies do not need contaminants making their daily functioning a misery. A majority have found numerous ways to ensure their environments have innovations that make life much easier and simple as well. Creating such surroundings demands that you consider materials used, filtration, dilution, and air movement or flow. All these should comply with particular standards and specifications.

If we look at materials used, we consider cleanroom panel suitable for preventing contamination. For many organizations, stainless steel and fiberglass have always favored organizations. However, HPL cleanroom panel has proven somewhat effective, especially since it is superfast and unfriendly to contaminants. At Wiskind factory, We have the best experience with cleanroom panels, as they hardly rust, retain moisture or withstand any harmful materials that could compromise quality control.

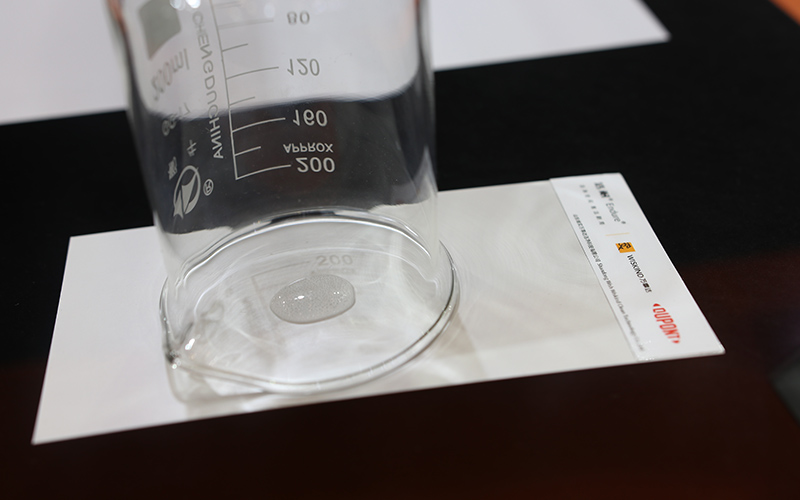

We also suggest antimicrobial coatings as creative mechanisms for improving cleanrooms. Although many equipment and surfaces come with such protective components,However, it turns out that the incorporation of disinfectants can produce bubbles on the surface of ordinary cleanroom panels, which greatly affects the use time of clean rooms and is also unfriendly to human contact.

Let us consider something more significant, like the process of cleaning and disinfecting operating environments. Which chemicals do you use? What methods do you find most suitable? These questions are rather crucial that you might think. At Wiskind, We ensure that all disinfectants and cleaning materials do not leave residue on the surface of HPL cleanroom panels. Remnants are a common issue in pharmaceutical industries, whereby some chemicals fail to eliminate certain substances.

We follow strict guidelines like those of GMP Guidance Annex, which advice manufacturing industries to use validated cleaning processes that remove impurities that can compromise sterility. Furthermore, using innovative means to create a sterile environment has proven beneficial. For instance, you can develop methods to measure and compare residues, including visual appearance, residue accumulation, and remnants on evaporation. This idea will help you identify which cleaning and disinfecting products to use as well as the best processes for a thorough outcome.

Another significant component to consider is how to transfer highly sensitive products from one cleanroom to the next. Not all materials are friendly with different facilities, mainly when it comes to functions like sealing, emptying, and filling, among others; their residue containment differs. We have professional designers to design the clean room with the most complex production process according to your production conditions and requirements to improve your production efficiency. We hope you will ensure an environment that will not harm you and your employees' health.

Previously, we mentioned that clean room disinfection is an essential aspect. The most important disinfection is VHP. In Wiskind, we recommend using Endure® to ensure that during the disinfection and sterilization process, the disinfectant in the environment will not Has an impact on the surface of the cleanroom panel. You should also invest in a HPL cleanroom door, especially on surfaces that require strict cleaning.

At Wiskind, we desire success and therefore extend the same to you by recommending modern approaches to innovations that make life easier in the cleanroom. We recommend computerized software in designing your space. Applications like Building Information Modelling (BIM) account for complex yet useful calculations like geometry, light analysis, spatial relationships, and geographic information. You can easily set an ideal clean room with quality management tools like Failure Modes and Effects Analysis (FMEA) or Hazard Analysis and Critical Control Points (HACCP).

All these innovations should be preferably energy efficient because it is significant in saving costs and the amount of carbon emission. At Wiskind we understand that cleanroom technologies provide more services than controlling contamination. Therefore, it makes life easier in our cleanrooms if we employ energy-efficient innovations. We install our HVAC parameters using the environmental standards approved, such as ensuring that the air released to the surroundings does not possess a concentrated amount of toxic elements. Both ventilation and air conditioning systems have advanced filters connected to a computerized system that controls emitted air. Visit www.wiskindcleanroom.com, and we shall be delighted to help you make turn your cleanroom into a sterile and productive environment.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.