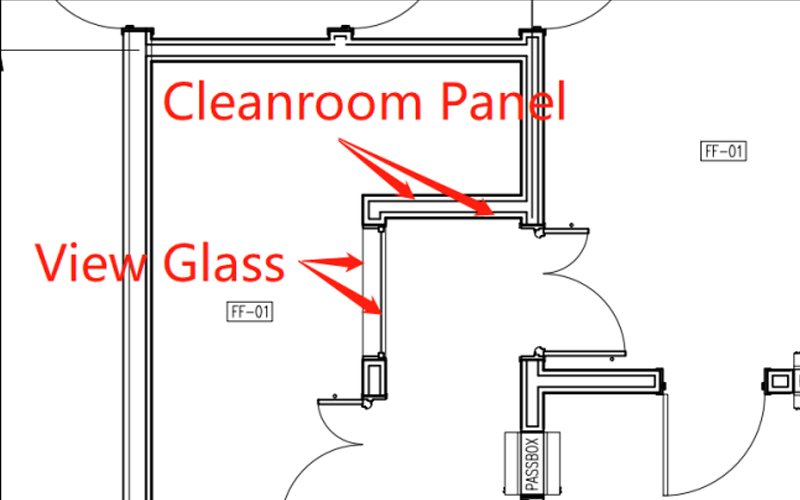

At present, the cleanroom windows on the wall of the return air clipway use two 50mm thick cleanroom windows, and the middle is sealed with a cleanroom panel. The cost of cleanroom windows is high, and the efficiency of on-site construction is low. Three people make four windows a day.In response to this problem, Wiskind has developed an assembly window covering technology.

Lead Time:2-7day

Product Orign:China/ShanDong

Wall Spacing: 350mm

Window Specifications:2363mm*1200mm

Return Air Wall:Blind Panel

Blind Panel Specifications:2424mm*348mm*10mm*2 1180mm*348mm*10mm*2 (Can be customized according to the size of the hole)

Fixtures & Pendants:Quantity 16

We have a passion for unconventional solutions that bring your vision to life.

At present, the cleanroom windows on the wall of the return air clipway use two 50mm thick cleanroom windows, and the middle is sealed with a cleanroom panel. The cost of cleanroom windows is high, and the efficiency of on-site construction is low. Three people make four windows a day.

In response to this problem, Wiskind has developed an assembly window covering technology. The cleanroom windows on the return air duct wall are assembled in a factory prefabricated assembly modular manner, which can greatly improve the work efficiency of construction workers on site and save cleanroom panel costs.

Window Specifications | 2363mm*1200mm |

Wall Spacing | 350mm |

Return Air Wall | Blind Panel |

Blind Panel Specifications | 2424mm*348mm*10mm*2 1180mm*348mm*10mm*2 (Can be customized according to the size of the hole) |

Fixtures & Pendants | Quantity 16 |

Installation Animation

We will contact you as soon as possible!

Modular Assembly Return Air Wall for Biological Cleanroom

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.