We have a passion for unconventional solutions that bring your vision to life.

After the arrival of the cleanroom panel at the project site, the construction personnel shall carefully check whether the model,cleanroom panel specification and quantity of each item are consistent according to the shipment schedule, and whether there is transportation damage, etc. If any problem is found such as lack or damage, the related customer service personnel of Wiskind shall be informed to solve it in time.

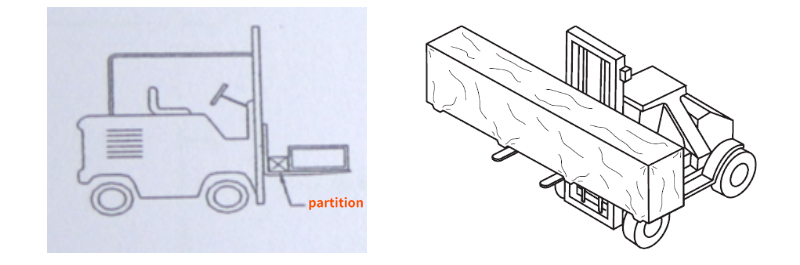

1) when using forklift shovel to unload, the forklift fork should be equipped with spacer to prevent scratches on the cleanroom envelop material.Move the forklift to a reasonable position in the cargo box of the truck, aim at the gap below the clean material and then unload the truck;The cleanroom panel should be balanced on the forklift to avoid slipping.

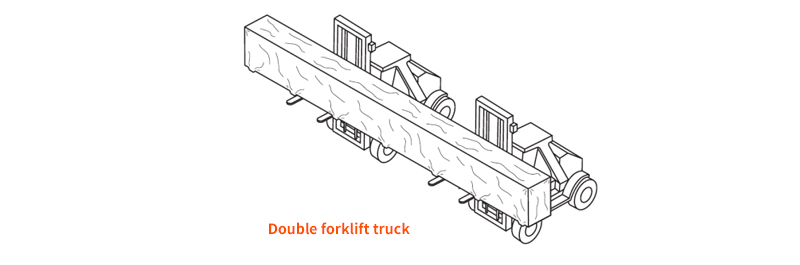

If the cleanroom wall panel is too long (8m or more), two or more lifting devices shall cooperate to unload the truck.

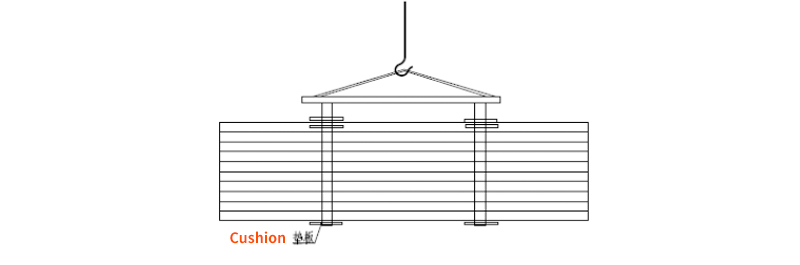

2) when using the crane to lift and unload, spacers shall be placed on both sides of the sling to prevent the sling from crushing the child and mother ports of the material, avoid affecting the installation and use, and put in an appropriate position for installation.

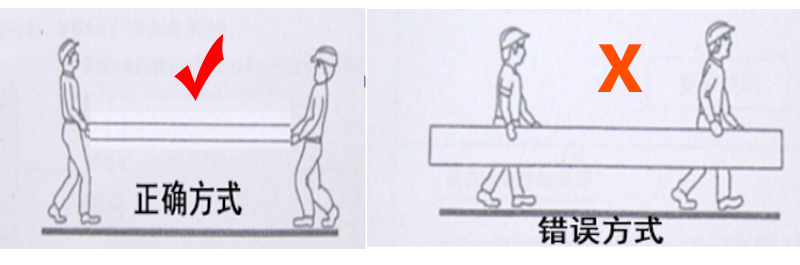

3)Manual unloading, handling personnel should wear gloves, grasp the cleanroom wall panel, edge strength of good position, force should be uniform, ensure the balance of the cleanroom panel, to prevent creases;Attention should also be paid to avoid collision between the cleanroom panel and the compartment, to prevent scratches;Do not drag material.

4) Depending on the length and model of the clean room panel, the number of carriers shall be selected. It is recommended to carry the clean wall panel with a spacing of 2000mm. When the spacing of the clean plate is ≥3000mm, additional personnel shall be added in the middle.After lifting the cleanroom panel to the installation area, place the clean board horizontally on the foam board and outward to facilitate the lifting of the next step.

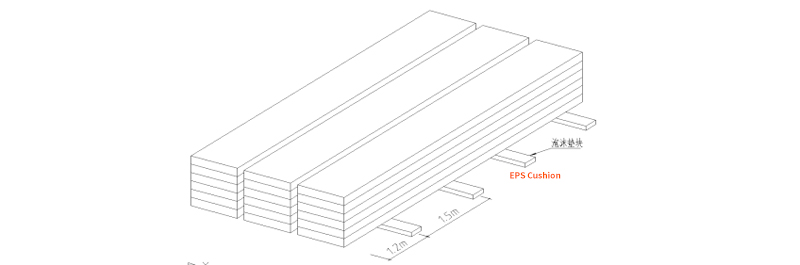

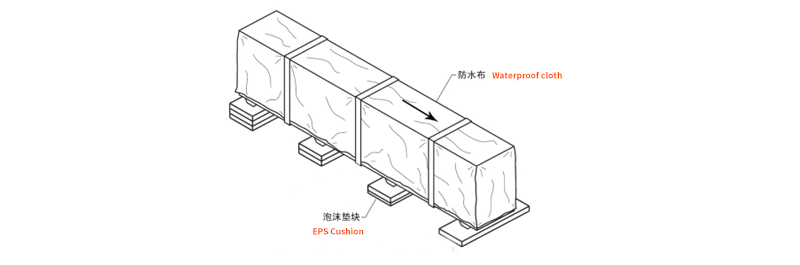

1) cleanroom envelop system material should be placed in the warehouse or shed as far as possible, if need to be placed in the open air, must support mat level (and keep 80mm clearance with the ground), the upper part of the intact rain cover, strictly prohibit rain, damp, water immersion.

2) when the clean room panel is piled up on the spot, the pad on the ground should be inclined to facilitate drainage;Piles of boards should have gaps between the sheaves;Cover with plastic or linoleum to prevent rain and snow;The lower part between the cover and the plate should be open to facilitate air circulation;Add warning signs and place safety items.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.