We have a passion for unconventional solutions that bring your vision to life.

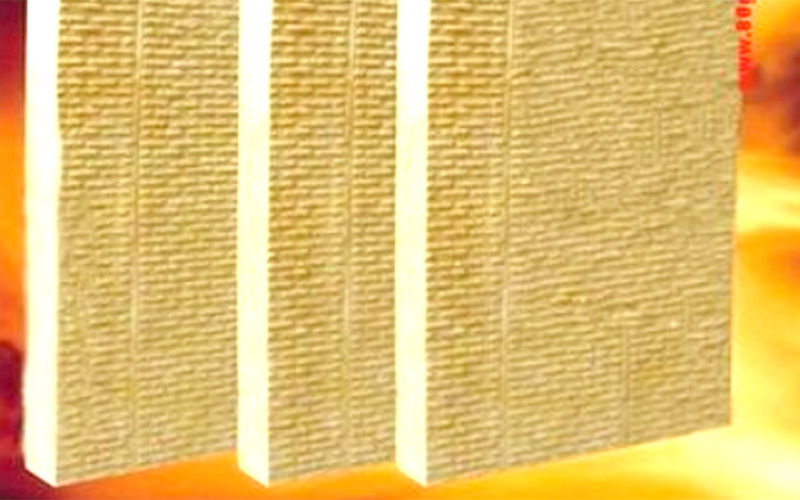

As a Class A fireproof material, rockwool is widely used in exterior wall insulation systems.Rockwool is used as building insulation material, especially in the field of public buildings where fire protection is required. The application volume has been steadily increasing. The superior performance of rock wool has become a common choice for customers. What is the difference between rock wool and slag wool? What is the difference between the two? Let me introduce the difference between rock wool and slag cotton!

The same point between rock wool and slag cotton:

1、All belong to mineral wool, which is a non-polar fibrous product formed by natural gas, or slag and other raw materials in a high-temperature furnace under the action of centrifugal force and wind.

2、The main components are silica, alumina, calcium oxide, and magnesium oxide, as well as less iron oxide; for molding, a small amount of phenolic resin is added.

The difference between rock wool and mineral wool:

Habitually, the product produced with slag as the main raw material is mineral wool, and the product produced by natural stone such as basalt and diabase is called rock wool.

Generally, the acidity coefficient is used as the main indicator to distinguish rock wool from mineral wool. The acidity coefficient refers to the ratio of the sum of the acidic oxides in the product to the sum of the basic oxides, ie, the acid-base coefficient MK=(silica + aluminum oxide) / (calcium oxide + magnesium oxide) acidity coefficient ≥ 1.6 For rock wool, the acidity coefficient <1.6 is slag wool. In general, the greater the acidity coefficient, the better the chemical durability of rock wool and slag wool. The rock wool has a high acidity coefficient, and its chemical stability and high temperature resistance are superior to those of slag wool.

The difference in chemical composition and acidity coefficient between rock wool and slag wool leads to some differences in their performance.

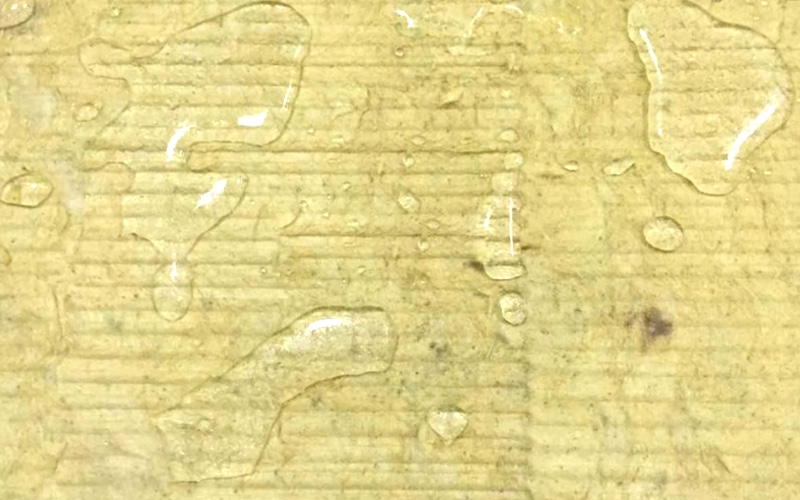

A、Chemical stability and water resistance

2CaO·SiO2 is rarely present in rock wool, so its water resistance is much higher than that of slag wool. The pH value of rock wool and slag wool is quite different. The rock wool is generally less than 4, which is a mineral fiber with particularly stable water resistance. The slag wool is generally more than 5 or even more than 6, and its water resistance can only be moderately stable or unstable.

In addition, corrosive impurities that may be contained in slag wool products are dissolved in water and corrode steel plates or metal fasteners. Therefore, only rock wool can be used in the insulation system inside the building, and slag wool cannot be used. For Wiskind rockwool cleanroom wall panels, high-quality cleanroom rock wool is used. After special water proof treatment, it does not absorb moisture, drowning, and has no capillary penetration. The drowning rate is more than 98%.

B、High temperature resistance

Rock wool has good high temperature stability and the melting temperature exceeds 1000 °C. The slag cotton fiber begins to devitrify at 500 ° C ~ 600 ° C, the fiber shrinks thickening, embrittlement agglomerates, loses the heat preservation effect, and is broken and powdered, so the temperature of the slag cotton should not exceed 675 ° C. Therefore, slag wool cannot be used in buildings.

C、Mechanical properties

The rock wool fiber has a higher acidity coefficient, and the silicon-oxygen bonded bridge oxygen bond is enhanced. In addition, the rock wool fiber has a small diameter (average of 5 μm or less), the tensile strength is increased, and the fiber strength is enhanced. The content of alkaline earth metal in the slag cotton fiber is high, which destroys the network structure composed of Si-O, weakens the bond strength and reduces the fiber strength. The fiber length is short (generally larger than 7um), the strength of the monofilament is low, and the mechanical properties are poor.

The distribution and solidification of rock wool resin binder used by Wiskind is relatively uniform, and the fiber is slender, and there are few non-fibrilated impurities such as slag balls. The bonding ability between fibers is strong, and the bending load is 1.1KN/㎡.

In fact, whether it is rock wool or slag wool, it will inevitably come into contact with metal and moisture in its use. Therefore, the difference in corrosion resistance between the two materials at the time of material selection cannot be ignored.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.