We have a passion for unconventional solutions that bring your vision to life.

Surface

The surface of cleanroom panel is clean, free of glue marks, material marks, oil stains and cutting burrs

Panel

(1) The surface of the panel is smooth, the color is uniform, and there is no obvious color difference, unevenness, warping, and deformation

(2) There are no obvious scratches, bumps and scars on the rest of the panels

(3) Replacement of panels in the production of the same order ensures that there is basically no visible color difference between the two panels on the same side

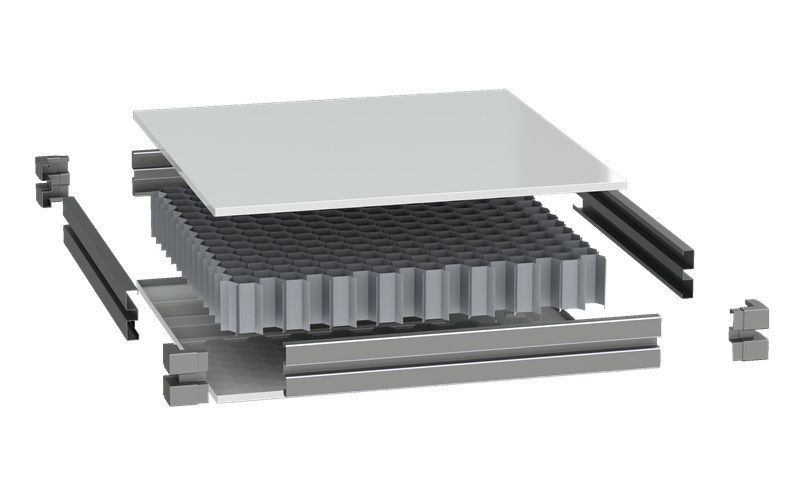

Substrate

(1) The substrate has no cracks and lack of material

(2) Coating and plating have no defects such as cracks and peeling visible to the naked eye

Core panel

(1) Cotton core material strips should be filled tightly and not loose, and there should be no gaps greater than 3mm

(2) The size of the sliver in the manual production line should not be less than 200mm

(3) The size of the sliver in the continuous production line should not be less than 300mm

(4) After dotting, the distance between the sliver and the keel shall not be greater than 10mm

Lamination

Wiskind’s film must be firmly bonded to the utility panel, and the film must be flat, without many wrinkles and large air bubbles, and there is basically no lift at the edge

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.