We have a passion for unconventional solutions that bring your vision to life.

With the advent of the era of 5G, the high-tech electronics industry has become the focus of people's attention. For the electronics manufacturers, the production environment cleanliness requirements are becoming increasingly high, and the environment with high cleanliness is producing high-quality products.

For the construction of plants, need to use new materials, caigang clean plate is one of them, it can be widely used in electronics, pharmaceuticals, food, biology, aerospace, precision instrument manufacturing and scientific research and other demanding environmental requirements of clean engineering fields.

Although clean room panel is widely concerned, but few people understand the cleanroom panel installation process and lap mode.Below Wiskind introduces to everybody, let everybody have a thorough understanding.

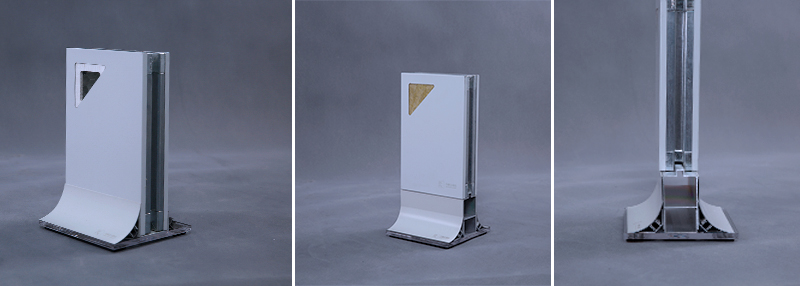

Cleanroom panel is divided into hand-made clean panel and machine cleanroom panels.The mechanism cleanroom panel is divided into socket type (socket lap) clean panel and port type (buckle lap) clean panel.

Hand-made cleanroom panel is divided into hand-made box panel and tongue and groove board.Among them, there are three kinds of lapping methods of hand-made box board: "middle aluminum partition lapping", "sandwich removable partition lapping" and "wide seam partition lapping", while tongue and groove board adopts the lapping method of child and mother mouth.

These lapping methods are weld-free lapping, and clean room panel is recognized by the general society, which is a great contribution to the weld-free lapping.The technological features of this weld-free welding lap joint are mainly reflected in the following:

1. Color cleanroom wall panel and clean wall panel connection on both sides of the mother slot, sealing effect is good, can reach high cleanliness;It has the characteristics of light weight, high strength, large adjustable installation, convenient and fast installation.It can also be processed into fireproof cleanroom wall panel with fireproof materials, which has very little influence on engineering structure.

2. The use of clean panel space will only be a simple plane space out of the processing size of the board, the board according to typesetting size processing.When connecting, fix the u-shaped groove with the ground, erect the clean plate into the geosyncline and connect the child and mother slots of the plate. Connect the upper mouth of the plate with the ceiling (the ceiling is clean plate).The Angle of Yin and Yang is covered with c-type aluminum, which is simple in construction and does not have high technical requirements.

3. The clean room panel installation inspection can be carried out simultaneously with the clean plate installation, the acceptance method is simple.The upper opening of the wall panel and the cleanroom ceiling panels are connected by self-tapping nails. The flatness and verticality of the board can be adjusted at any time to ensure accurate, safe and rapid construction.

4. Because the construction of clean room panel is completed in one time, there is no need to carry out other construction on its surface. Materials used in the market are spot, no processing period, no impact on the construction period, and environmental health, performance to meet the requirements of environmental protection, and has the characteristics of reusable, both by qi and affordable.

The installation process of clean board is as follows:

1. Construction criteria → 2. Measurement and setting out →3. Boom installation →4. Installation of t-type aluminum →5. Geosyncline installation →6. Roof installation →7. Wall panel installation →8. Accessories installation →9. Hole cutting →10. Doors and Windows installation →11. Clean seal.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.