We have a passion for unconventional solutions that bring your vision to life.

Recently, the website background received a large number of customer messages said: clean room panel after the use of disinfection, color steel plate cleanroom panel surface will be corroded, a large number of bubbles, at the same time in the use and installation of clean room panel in the process of scratch problems.Can we have a good plan, instead of replacing the clean room panels and saving the cost?

Wiskind to answer questions raised for customers, first, to clean room panel surface scratch problem appeared in the process of use and installation, clean the surface of the plate is damaged, protective film did not play the role of protection, while most of the customer when buying clean room panel will not care about this a little detail, but can very good protect clean room panel surface protective film, in the process of installing efficiency, eliminating the replacement time, installed more beautiful in the future.

When selecting a clean plate, ask the manufacturer, the protective film is a few silk, most manufacturers are using wire protective film, and the common bonding strength, can't have very good protection effect on the surface of a sheet, Wiskind cleanroon panels protective film, 8-12 silk, can have very good protection around to clean room panel, prevent clean room panel surface scratches, 1000 - square - meter board common membrane with artificial 10 to 15 people, 4-6 people, Wiskind protective film with artificial cost savings.

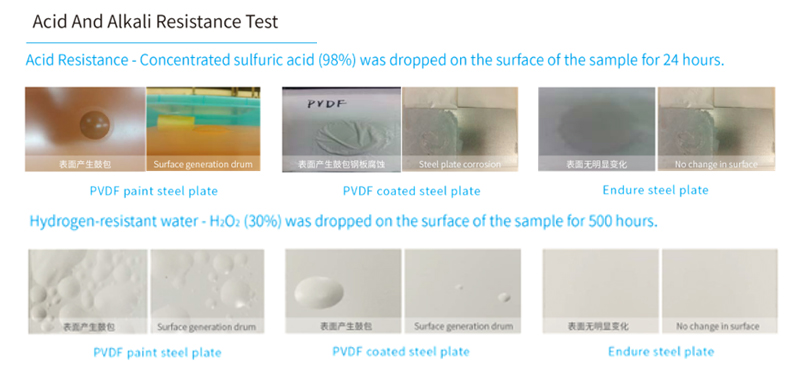

As for the problem of air bubbles and corrosion on the surface of clean room panel after using disinfection, Wiskind invented a new product -- Endurer, which can effectively prevent the problem of corrosion on the surface.In order to meet the requirements of clean room GMP article 11, clean area surface should be smooth, no cracks, tight interface, no particulate matter off, and can be resistant to cleaning and disinfection.Specifically, we have carried out experimental testing on the clean surface (four testing items: non-flammable testing, tearing strength testing, anti-pollution and anti-friction testing, and heavy metal testing), and it has been proved by the experiment that:

In order to better understand its material characteristics, ensure product quality requirements, and meet the requirements for materials used in clean rooms, Wiskind adopts the attitude of being responsible for customers and enterprises, and adopts professional instruments and equipment to test it -- experimental comparison of hydrogen peroxide resistance of different paint layers.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.