We have a passion for unconventional solutions that bring your vision to life.

1. The layout of the workshop:

First of all, regardless of any structure of the purification workshop of a food factory, the primary problem is the design of the layout of the workshop. The design difficulty is that its layout should not only facilitate the interconnection of various production links, but also facilitate the sanitary control of the processing process to prevent the occurrence of cross-contamination in the production process.

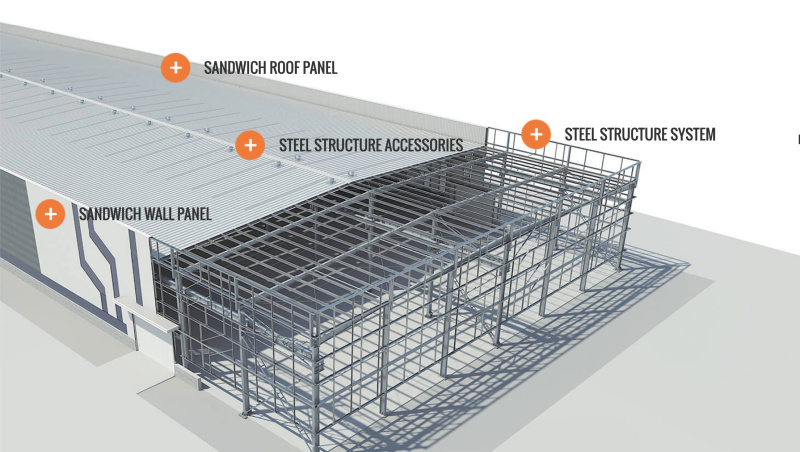

2. The structure of the workshop:

Secondly, the structure design of the food factory workshop purification is suitable for the special requirements of specific food processing. The editor believes that steel-concrete or brick-built structures should be the mainstay, and according to the needs of different products.

WiskindGroup was founded in 1978, mainly engaged in construction steel products and cold rolled steel coil manufacturing, coated steel trade and other businesses.Shandong Wiskind Architectural Steel Co., Ltd.is a professional manufacturer and service provider of metal enclosure and steel structure products, and a national high-tech enterprise. Over the past 40 years,Wiskindhas enjoyed a good reputation both at home and abroad. Its construction steel products are widely used in industrial manufacturing, logistics and storage, modern agriculture, public buildings, transportation and commercial facilities and other fields, contributing unique value to the progress and development of various industries.

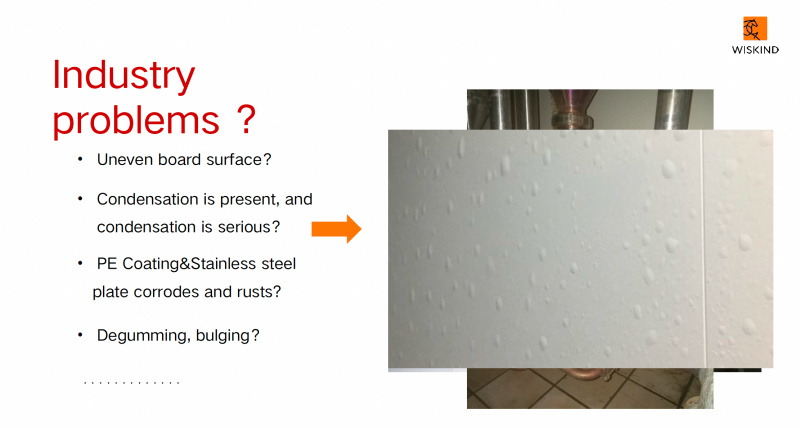

3. The floor, wall, top surface, doors and windows of the workshop

The level of the entire floor of the workshop should be slightly higher than the ground level of the factory area during design and construction. The floor surface of the workshop should be flat, free of water, and have slopes at the edges. In addition, the floor of the workshop should be made of non-slip, sturdy, impermeable, easy-to-clean, and corrosion-resistant materials.

The Wiskind clean room system can provide different solutions for food workshops

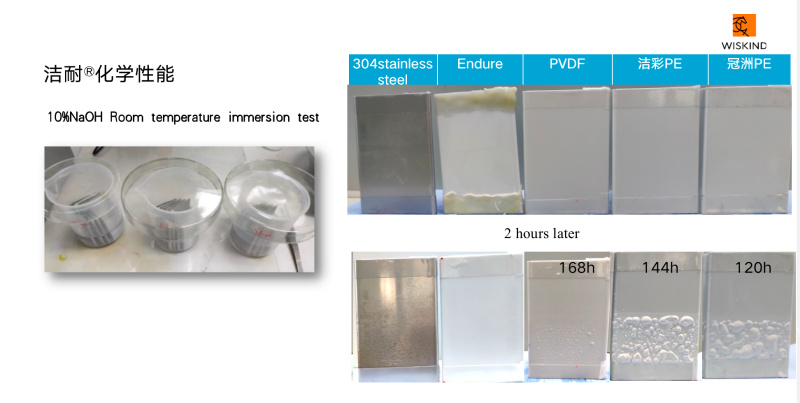

1. Stainless steel wall panel

2. PVDF wallboard

3. Endure wallboard

The three kinds of wall panels have different advantages in different environments

4. Water supply and drainage facilities

The drainage ditch of the workshop should be paved with smooth and impermeable materials. There should be no unevenness and cracks during the construction, and a 3% inclination should be formed to ensure the smooth drainage of the workshop. The water supply pipes used to purify the production water in the food factory workshop should be made of pipes that are not easy to rust, and the water supply pipes should be uniformly routed asfar as possible.

Wiskind R&D Center has always been committed to developing new products. For the food workshop, we have developed different series of anti-sink, which is convenient for the workshop to wash the ground and not easy to rust.

5. Temperature control facilities:

The workshop for processing perishable and perishable products should be equipped with air-conditioning facilities. The temperature in the meat and aquatic product processing workshop should not exceed 15°C~18°C in summer, and the temperature in the marinating room of meat products should not exceed 4°C.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.