We have a passion for unconventional solutions that bring your vision to life.

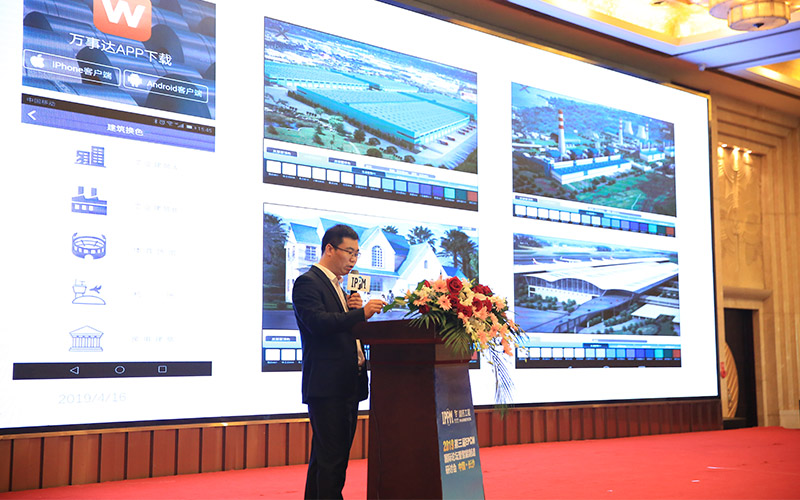

On April 16, 2019, during the Changsha Pharmaceutical Opportunity, the 3rd EPCM Pharmaceutical Engineering International Forum and Intelligent Manufacturing Seminar was held.Mr. Liu Shilin, the representative of Wiskind Cleanroom, made an important speech. The modular construction of the cleanroom enclosure system and the environmentally friendly concept were widely recognized. The diversified solutions of high-tech innovation became the forum hotspot.

Liu Shilin, R&D Manager of Wiskind Cleanroom Research Center, focuses on cleanroom enclosure system solutions and intelligent manufacturing. From the aspects of building modularity, functional integration, BIM-based technical services, and environmental friendliness, the Wiskind concept and technological innovation are demonstrated. Leading the future development of industry technology.

Wiskind Cleanroom Enclosure System adopts a prefabricated design concept and adopts a modular construction method to respond to the pharmaceutical industry upgrade with a high-efficiency, high-standard cleanroom. The national patented corner plate technology, detachable system, integral return air wall panel and assembled hole system have greatly improved the design and construction level of the clean room from the aspects of structure, materials and construction, and realized clean functional integration: Insulation and energy saving, anti-cold bridge, antibacterial, VHP disinfection, etc.

In terms of intelligent manufacturing applications, Wiskind pioneered the clean line automation production line, subverting traditional hand-made methods with digital production, flexible production and lean production modes. The flatness and verticality are strictly controlled by quality. In particular, the adhesive rooting technology and the automated computer metering and coating technology solve the problem that the traditional process is greatly affected by human factors and the error is difficult to control, so that “the quality of each cleanroom panel is the same”.

In addition, steel cleanroom doors have established automated production lines and processes, all imported Italian automatic plate machines, automatic cutting, playing, Japan Yaskawa robots, Toyota car welding process, from the source to ensure accuracy and quality. In the future, Wiskind Cleanroom will form an intelligent cleanroom door and window system.

Provide technical solutions to customers through digital construction. Create a more humane cleanroom for customers, making the working environment richer and warmer.

In the forum, Wiskind booths were favored by everyone, and the overall corner panel technology and Jiecai professional color steel plate attracted many guests' consultation.

The representatives of the whole industry chain technology flow jointly carried out in-depth discussions on hot issues such as EPCM project contracting in the pharmaceutical industry, pains in engineering practice, automation and informationization in the pharmaceutical field, and industry development policy trends in China and North America. Service innovation and healthy ecology have played an active role in promoting.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.