We have a passion for unconventional solutions that bring your vision to life.

Our vaccines are not only abundant, but also completely free.

But do you know what kind of effort is behind this little vaccine?

This is a kind of temperature, embodies the care of the party and the country, and is the most precious gift to the people;

It is the crystallization of the research team, virus experts, and manufacturers sweating and guarding day and night.

Since the outbreak of the epidemic, the State Council’s Joint Prevention and Control Mechanism Scientific Research Team has set up a special vaccine research and development team, following five technical routes: inactivated vaccines, recombinant protein vaccines, adenovirus vector vaccines, attenuated influenza virus vector live vaccines, and nucleic acid vaccines.

Global participating vaccine R&D companies include SINOVAC, CanSinoBIO, HUALAN BIOLOGICAL, Cloverbiopharma, etc.

And these different vaccine research and development companies chose the same Wiskind.

Back-up protection requires the construction of high-standard clean rooms, and vaccine production is different from other drug production. It must be carried out under aseptic conditions throughout the production process. Therefore, the design of vaccine production workshops must meet the requirements of GMP and exceed the standards to avoid During the production process, the indoor air cleanliness does not meet the requirements of the production process, causing pollution.

High-standard clean room construction is inseparable from high-quality enclosure materials. As a global service provider in the field of clean room enclosure systems, Wiskind provides more than 200,000 square meters of clean room enclosure materials for multiple vaccine research and development companies, and participates in multiple biological Pharmaceutical (vaccine, blood products, monoclonal antibody, cell therapy, insulin, etc.) workshop project.

Wiskind realizes modular installation in products, and provides different enclosure system solutions in different industry application environments, especially for hot issues such as resistance to VHP disinfection in biological clean rooms. High concentrations of hydrogen peroxide will produce color steel plates. Corrosion, Wiskind launched Endure® plate, as a special steel plate for the pharmaceutical industry, its unique properties include excellent resistance to VHP disinfection, excellent wear resistance, easy to clean, safe and environmentally friendly.

In the face of the urgent needs of the new crown pneumonia in research and development, "the time is tight, the project is large, the task is heavy, and the whole process is rushed to work" has become synonymous with the project. For projects with tight schedules, heavy tasks, and large volumes, Wiskind adopts the "iron triangle" model. During the execution of the project, sales understand customer needs and do a good job of internal and external leadership. The technical support department does a good job of providing services, while Wiskind develops a smart space design system to reduce designers' repetitive layout work on the design side, save a lot of time and improve production efficiency.

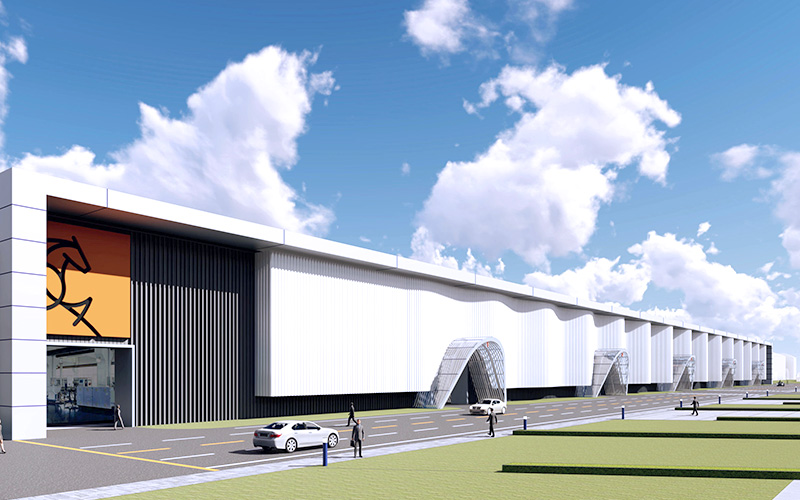

At the manufacturing end, we have the world's first cleanroom panel automatic production line with independent intellectual property rights. The Wiskind Jiangsu plant will be located in Zhenjiang in June 2020, with a new production workshop of 60,000 square meters, and an annual production base of 8 million square meters of fully automatic, green and high-performance enclosure system products. The contract performance department is a good delivery officer, and each department is coordinated and efficient, with a clear division of labor, each performing its own duties, and delivering on time to customers.

Create the most powerful weapon for the human battle: multi-party force

"Humanity is a community with a shared future. To overcome the epidemics that concern the safety of the people of all countries, unity and cooperation is the most powerful weapon." In the face of the menacing epidemic, vaccines have become a powerful weapon for epidemic prevention and control. Wiskind guarantees product quality at the rear and provides a full range of services. The integrated service builds a solid barrier for the construction of a professional vaccine clean room.

Wiskind is willing to work with everyone to add luster to "Made in China", give full play to the advantages of the industry platform, and make every effort to fight the epidemic prevention and control science and technology war, and contribute to the country and people.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.