We have a passion for unconventional solutions that bring your vision to life.

On November 3-5, 2020, the 59th (Autumn 2020) National Pharmaceutical Machinery Expo opened at Chongqing International Expo Center.

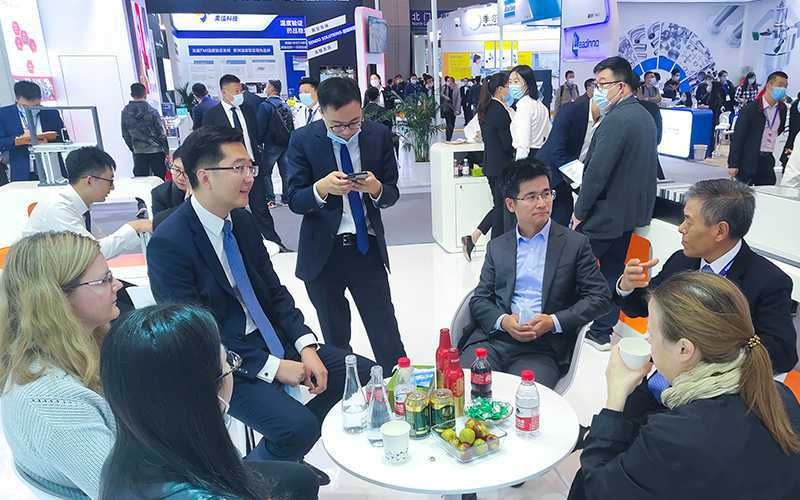

This year’s expo received a total of more than 500 domestic and foreign customers and attracted 1,340 exhibitors from 30 countries and regions. It is recognized by the industry as being professional, international, large-scale, full of exhibits, and a large number of visitors. It also integrates trade and seminars. An integrated communication platform for the pharmaceutical equipment industry.

At the same time, at the 14th Solid Preparation Equipment and Process Technology Forum on November 2, Jason Wei, Director of Wiskind Technical Center and Chief Engineer of Envelope Structure, launched a clean room enclosure system solution to capture the most concerned domestic and foreign The pain points of the clean room industry are shared with everyone around smart design, smart delivery, and environmental friendliness. The atmosphere on the scene is active and the response is enthusiastic.

Wiskind (Booth: International Hall C-52-2) made a strong appearance at this exhibition with self-developed new products, which attracted the attention of many exhibitors and received extensive attention from the industry. If you want to say nothing, please follow Let's see the demeanor of the scene.

One of the most concerned products is Wiskind Endure®, which is immersed in 10% hydrochloric acid and 10% sodium hydroxide at room temperature for 1208 hours without any changes on the surface.

In addition to the unique resistance to VHP disinfection, the finish of Endure® is matte design, the color is shell white, the visual effect is good, the surface is fine and uniform, the gloss is 8-10 gloss units, the color difference is small, and the color difference of the same batch △ E<0.3, the color difference of different batches △E<0.5.

As the most trusted company in the field of clean room enclosure systems, Wiskind focuses on technology, market-driven, and customer-centric. It adopts a modular design concept and uses a functionally integrated construction method to focus on structure, materials, and construction. Focus on the research and development of innovative technologies and solutions for clean room enclosure systems, and create high-end clean rooms for life sciences, food industry, and cutting-edge manufacturing.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.