We have a passion for unconventional solutions that bring your vision to life.

Food Security after the epidemic?

With the normalization of the epidemic and its profound impact on the economy and society, people's attention to food safety and nutrition has reached an unprecedented height. The food safety incidents that continue to break out in the society, especially the nutritional catering for students, have made countless parents full of worries and made people put forward higher requirements for the food industry.

At present, the nutritional meals for students in China are uneven, the industry standards are not uniform, the design of the factory buildings is backward, and there are few modern equipments. Looking at all aspects of the conditions, it is difficult to meet the requirements for the nutritional meals for students in the new era. The director of the China Safe Food Promotion Office has repeatedly mentioned the "central kitchen" model in public, believing that it is a new way of thinking about food safety.

What is central kitchen?

The central kitchen mainly refers to the center of centralized catering and distribution. The main task is to uniformly clean, decompose, and mix the ingredients and ingredients required by the restaurant through standardized operations and management, and then distribute them to each store for secondary heating, or sell them to customers after combination.

As a professional nutritious fast food company, Shizhicai mainly serves students, employees of enterprises , and provides professional services of nutritious, hygienic and delicious food.

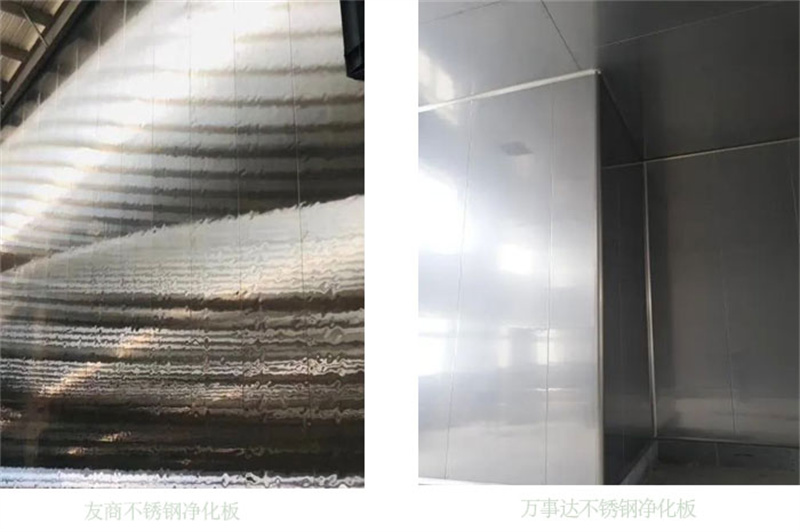

The central kitchen it uses includes vegetable cleaning area, meat processing area, oil plant area, cooking area, aquatic product processing area, etc. The construction of different areas needs to avoid the environment caused by high oil, high temperature, high humidity, disinfection, organic solvents, etc. Therefore, the requirements for the panel are extremely strict, and a little carelessness will cause the problem of bulging and blistering of the panel

As the first enclosure system service provider to enter the central kitchen field, Wiskind has accumulated many application environment solutions. According to different environments, Wiskind has different panel options, such as color-coated cleanroom panels, 304/316L stainless steel cleanroom panels, and Endure®, providing unique value to customers in the professional field.

Color steel cleanroom panel

Stainless steel cleanroom panel

Endure®

In terms of production process, Wiskind cleanroom panel is produced by the world's first continuous production line with independent intellectual property rights. Precise glue cloth, automatic cotton cloth, 31m double track hot pressing forming, the precision, strength and flatness of the cleanroom panel are extremely improvement, truly achieve "Technology makes good quality for each cleanroom panel".

As we all know, the central kitchen needs to be washed frequently due to the cleaning and disinfection of processing utensils and cooking, and there is a large amount of water accumulation, which not only corrodes the external steel panel, but also affects and destroys the weighing and structure of the panel. Therefore, when installing the cleanroom panel and the ground, it is necessary to do a good job of waterproofing the groove. For the waterproof problem, Wiskind launched a brand-new stainless steel floor tank waterproof node, which completely avoids the problem of corrosion and foaming on the panel surface due to washing, which affects the service life of the plant.

In the past few years, central kitchens, a name that is both familiar and unfamiliar to consumers, are becoming the key to transforming the supply chain of the catering industry. Central kitchens are rising rapidly, opening a new round of revolution in the kitchen industry. In the field of food clean room, Wiskind has accumulated rich industry experience, product concept of integrated solution, exerts its own advantages in the construction of standardized central kitchen, and makes every effort to clean and "enclose" food safety and health.

Shizhicai (Tianjin) Fast Food Distribution Service Co., Ltd.

Application system: stainless steel cleanroom panel, cleanroom door, cleanroom window

Area:22,000㎡

Thickness:50mm

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.