We have a passion for unconventional solutions that bring your vision to life.

The World Cup in Qatar has started,

the major countries have appeared

on the green field one after another.

This is a football feast for fans all over

the world. We shout for The World Cup,

and also cheer for the continuous

breakthroughs in cleanroom space innovation.

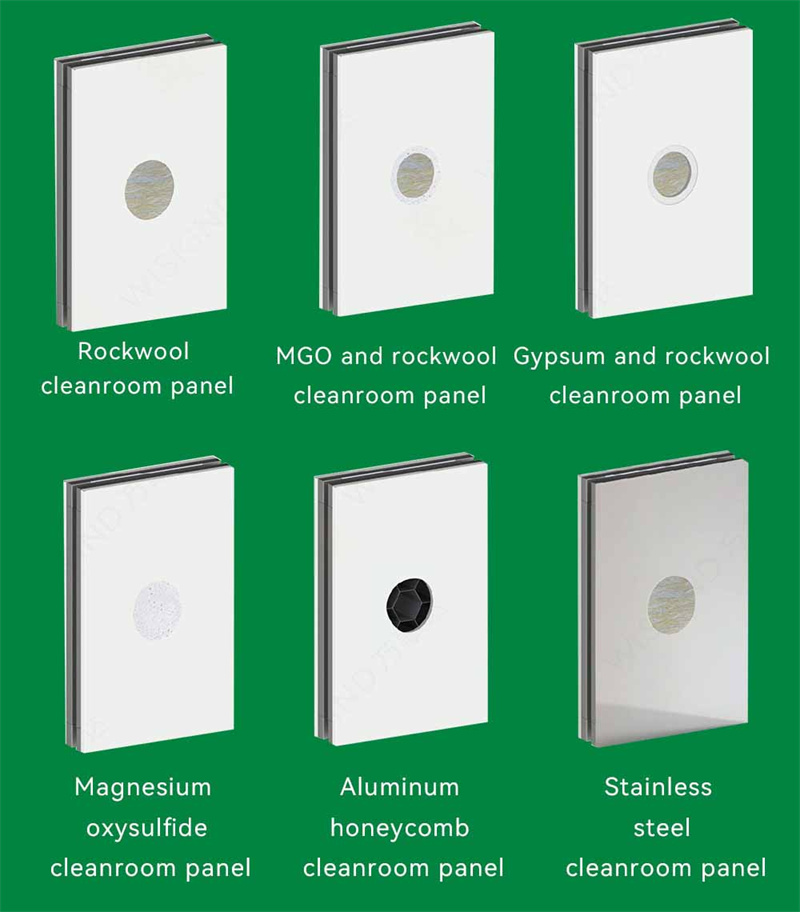

From reasonable structural design,

to the layer-by-layer selection of surface

materials, core materials, and adhesives,

to continuous optimization and

development of a more intelligent

continuous production line. It is in order

o composite a smoother panel surface,

with characteristics of unique dust-proof,

anti-static, anti-bacterial,

sound-absorbing, sound-insulating,

fire-proof and anti-bending.

Higysteel® is the product of the cooperation

between Wiskind and Baosteel Joint Laboratory,

a color-coated panel more suitable for

industrial cleanroom space. The whiteness

is increased by 4 units, the precision control

level of color difference is increased by 60%.

Reducing visual fatigue caused by glare in

the cleanroom. A breakthrough in technical

operation, focusing on creating an

environment-friendly cleanroom space.

Endure® is mainly suitable for the use of

VHP disinfection, alcohol, promethamine

wipe and other disinfection environments,

it’s a special panel for biological cleanroom.

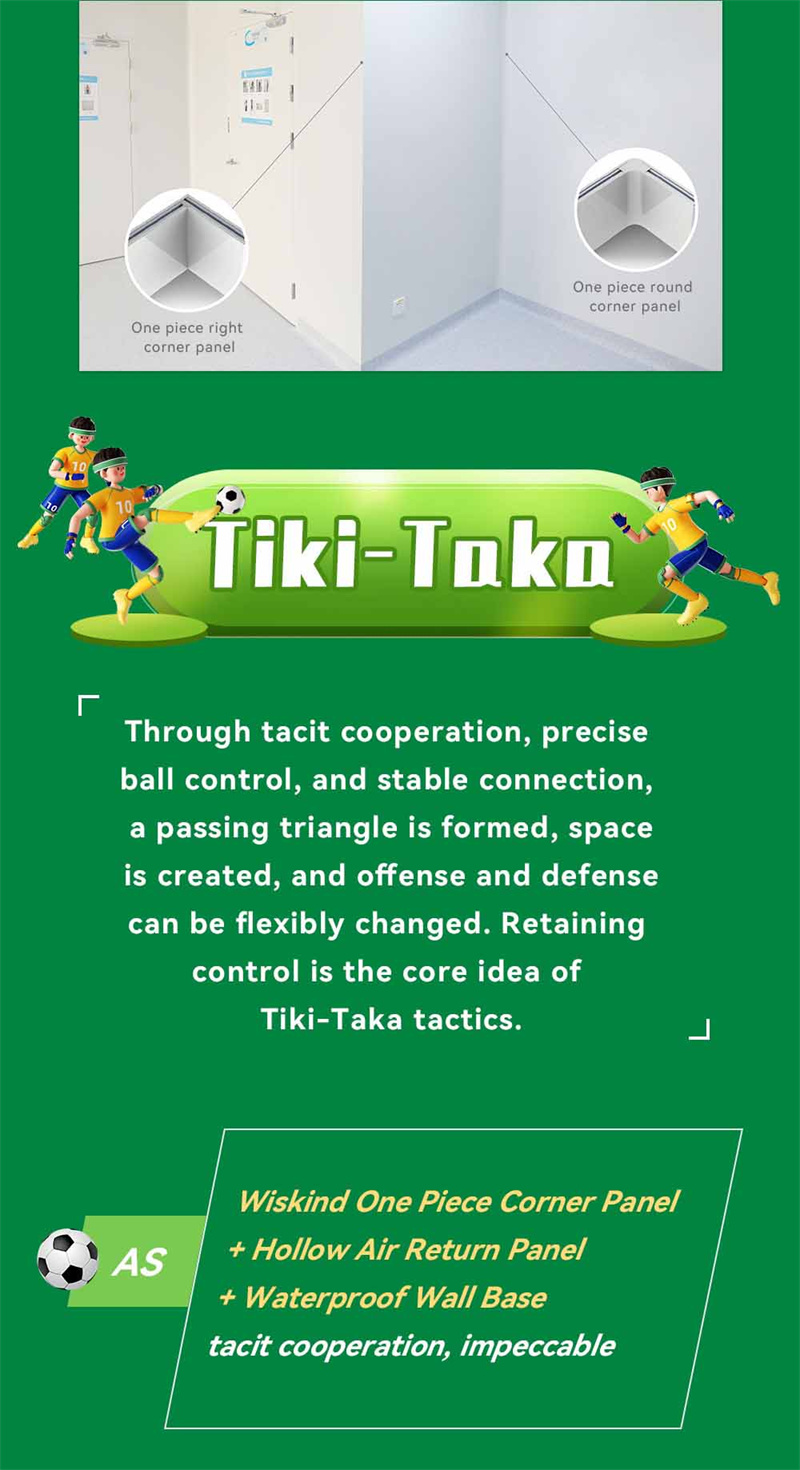

One piece corner panel is a patented product

of Wiskind. Different from the traditional

corner splicing combination, many aspects

take the initiative. The corner position is

smooth and seamless, and the interface is

tighter to prevent air leakage and dust

accumulation at the joint. It’s convenient

for cleaning and disinfection. Special heat

preservation treatment can effectively

avoid the thermal bridge effect common

in traditional corners. The panel can be

disassembled separately, which is convenient

and flexible for daily maintenance.

Wiskind launched the hollow air return unit

module 3.0 plus, which can replace the air

return column and 100mm hollow shrapnel

wall in the buffer room for changing clothes

and taking off shoes. The average return air

volume is 500m³/h , which greatly improves

the use of cleanroom space.

The stainless steel waterproof wall base is

to solve the problems of waterproofing of

the wall base in the food processing area

and the breeding of bacteria in the corner

of the wall. With 304 stainless steel as the base

material, it is manufactured and shaped

through integral pressing, welding and grinding.

It has a good waterproof effect in corners,

wrapped columns and other areas. It is

a new type of waterproof wall based product.

The feast is still being staged. On the court,

not only personal skills, speed and strength

are considered, but also teamwork. Wiskind cleanroom

focuses on the R&D and manufacturing of cleanroom

enclosure systems, is committed to breakthroughs

in technology application, and leads the development

of cleanroom enclosure systems with innovation!

Wiskind will join you in carnival for football!

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.