We have a passion for unconventional solutions that bring your vision to life.

The harm of static electricity to cleanroom

There are many occasions in the indoor environment of cleanroom where static electricity hazards exist, which can lead to damage or performance degradation of electronic devices, electronic instruments and electronic equipment, or cause electric shock injuries to the human body, or cause ignition or detonation in explosion or fire hazardous areas, or cause dust adsorption to affect environmental cleanliness. Therefore, the design of clean factory projects must attach great importance to anti-static environment design, and clean factories should take electrostatic protection measures according to process production requirements.

How static electricity is generated

Molecules, atoms and electrons of different substances have different attractions to each other. When two different substances come into contact with each other, charges can be generated instantly. This charge is called electrostatic charge. In daily life, when we walk across synthetic carpet in a dry, air-conditioned room, a charge accumulation of over 1,000 volts can occur.

How to prevent static electricity on cleanroom panels

Generally speaking, clean factories achieve the purpose of anti-static by increasing the humidity of the place of use to suppress the generation of static charges; Or achieve anti-static purposes by structurally modifying polymers, using conductive equipment, and using conductive polymer materials.

Influencing factors | Antistatic effect |

Ambient temperature | Proportional |

Ambient relative humidity | Proportional |

Antistatic material surface concentration | Proportional |

Cleanroom panels mainly achieve anti-static effects by increasing the surface concentration of anti-static materials. Wiskind's cleanroom panel uses high-end technology on the basis of ordinary modular cleanroom walls and uses a special substance to wrap the outside of TiO2 as a conductive electrostatic carrier. The use of TiO2 makes the physical and chemical properties of the electrostatically conductive carrier itself more stable than other electrostatically conductive carrier systems, and can also be colored. Based on actual usage needs, Wiskind can provide cleanroom panel that meet the requirements from point shielding to insulation to meet the static electricity control requirements of various electronic cleanroom.

| Classification | Conductive | Electrical Shielding | Antistatic | Insulation |

| Surface ResistanceΩ/㎡ | 103 | 106 | 109 | 1012 |

| Volume ResistanceΩ/㎡ | 102 | 105 | 108 | 1011 |

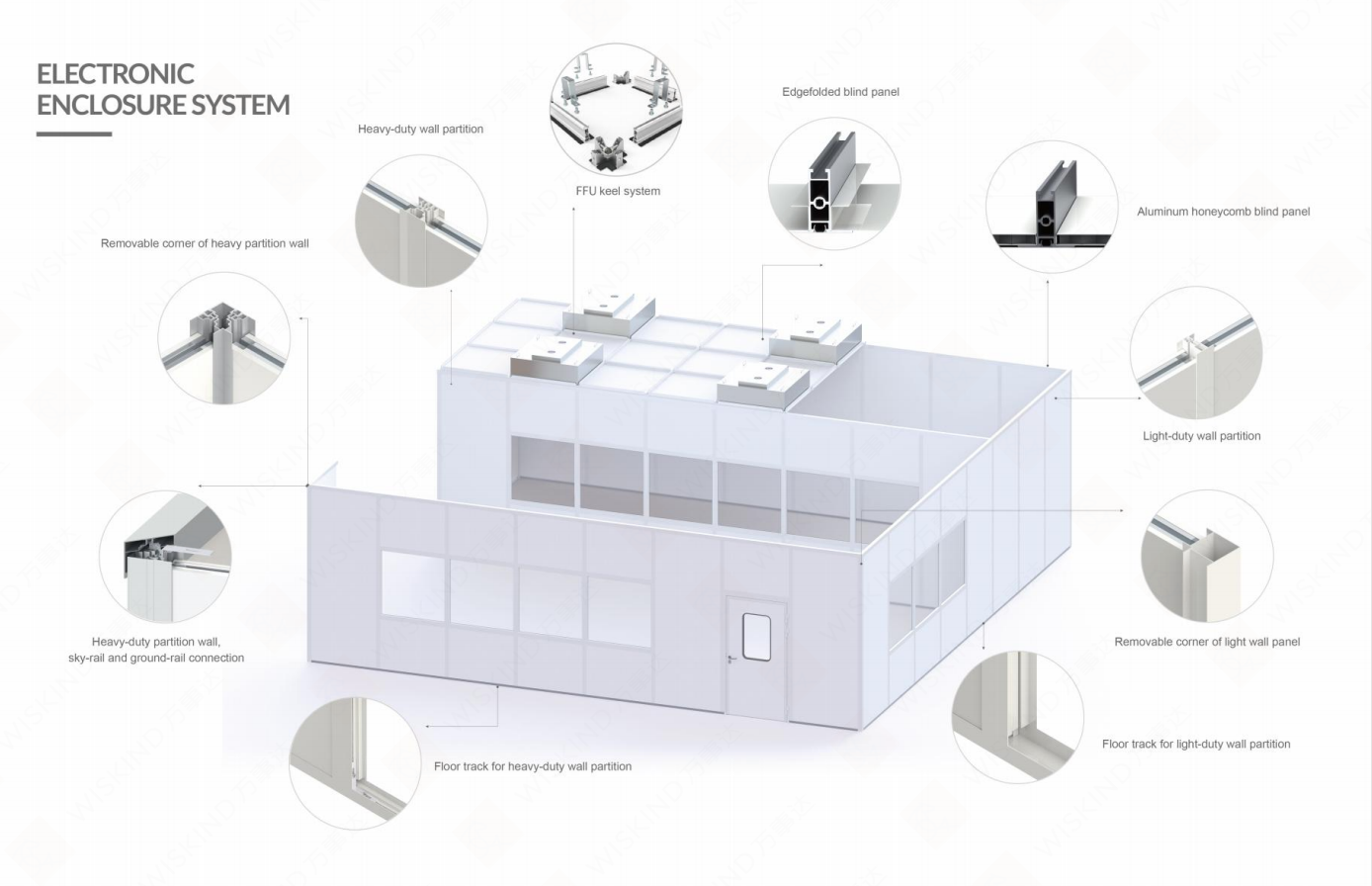

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.