We have a passion for unconventional solutions that bring your vision to life.

How Pharmaceutical Cleanroom Panels Can Withstand VHP Disinfection

What is VHP Disinfection Technology?

VHP (Vaporized Hydrogen Peroxide) is a sterilization technique that utilizes the superior spore-killing ability of hydrogen peroxide in its gaseous state compared to its liquid state at room temperature to achieve complete sterilization.

Why Ordinary Cleanroom Panels Cannot Be Used in Areas with VHP Disinfection?

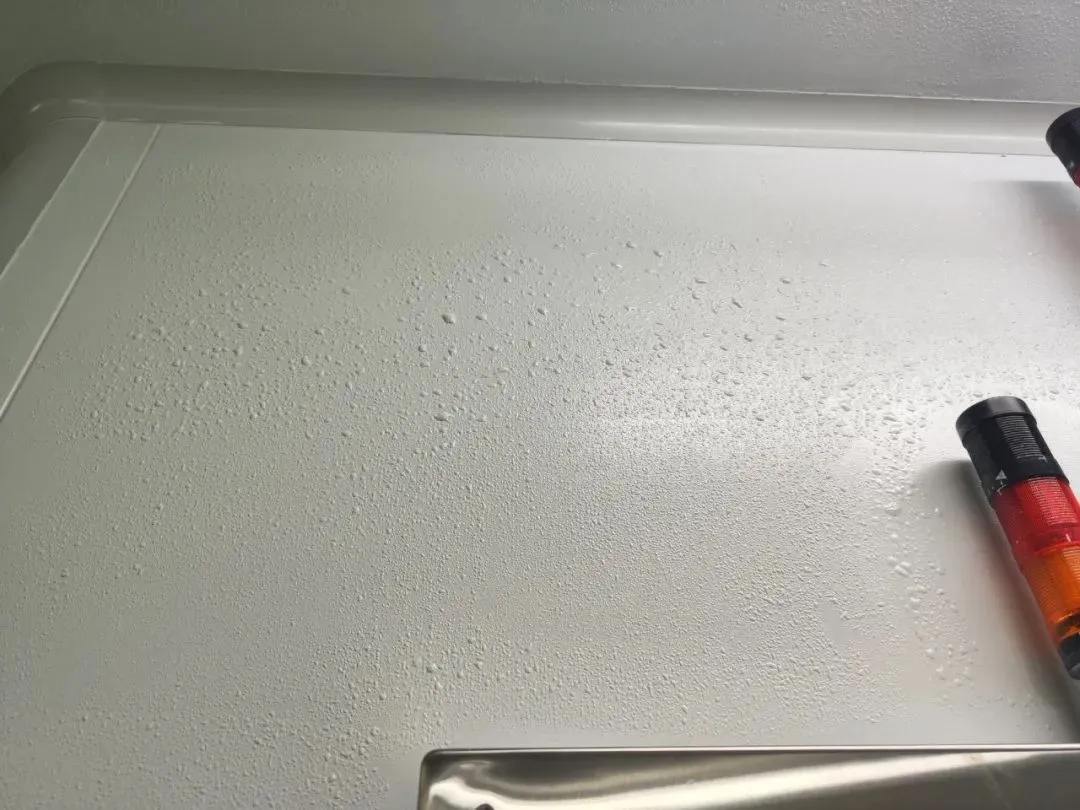

During hydrogen peroxide sterilization and disinfection, the primary mechanism is oxidation, which releases a large number of molecules to destroy the structure of microorganisms, thereby achieving sterilization and disinfection. However, the surface of color steel plates contains tiny micropores, allowing hydrogen peroxide molecules to penetrate between the coating and the steel plate, decompose into water and oxygen, and cause blistering due to their inability to escape. This can also lead to chalking, discoloration, and other phenomena.

How Are VHP-Resistant Cleanroom Panels for Pharmaceutical B-Zones Made?

Currently, pharmaceutical companies generally employ three methods to address the VHP resistance issue of cleanroom wall panels, all of which involve modifying the surface steel material of the cleanroom panels.

Stainless steel panels: This method fundamentally eliminates the problem of steel plate paint corrosion. However, besides the higher cost, stainless steel panels have the drawbacks of being unsightly, glaring, and blinding, making them unsuitable for use in small rooms.

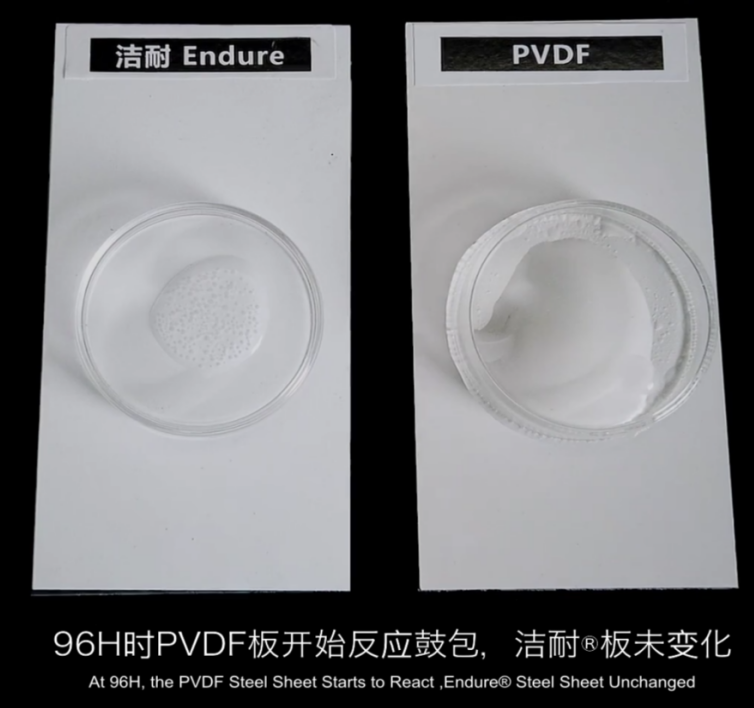

PVDF coated color steel panels: The surface density of this coating is higher than that of ordinary color steel panels, making it more resistant to corrosion. However, in actual use, when the hydrogen peroxide concentration is too high, it is still difficult to effectively solve this problem, making it an incomplete solution.

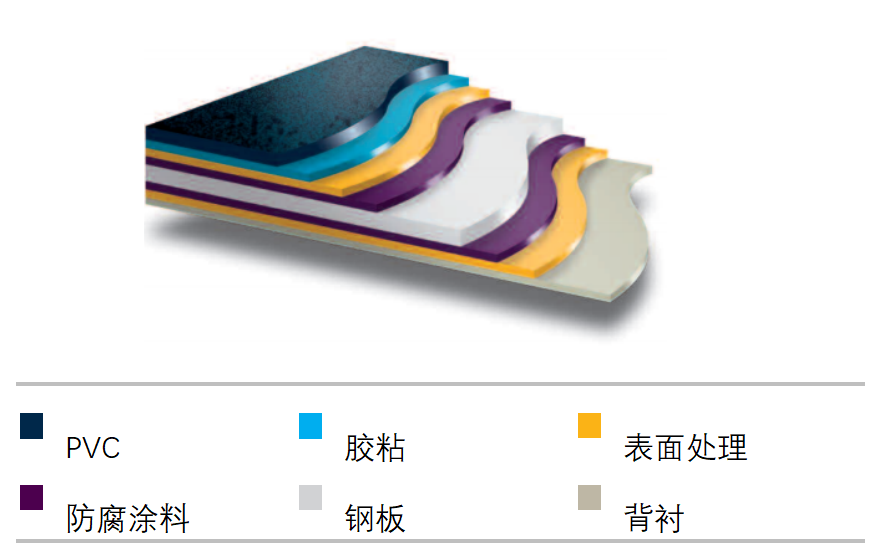

Endure® panels: Endure® panels are specially designed for use in VHP disinfection, alcohol, and Newcleanse wipe environments in cleanroom B-zones for biological products, blood products, and other applications.

Superior Performance of Endure® Panels

The unique structure of Endure® panels provides them with excellent chemical resistance, wear resistance, ease of processing, low glossiness, and aesthetic design. As can be seen from the results of the 30% hydrogen peroxide cup test, PVDF panels start to blister after 96 hours, while Endure® panels still maintain good resistance after 6000 hours of testing.

Project Cases Using Endure® Panels

Junshi Bio, RemeGen, and 3SBio Inc. are among the first domestic pharmaceutical companies to use Endure® cleanroom panels. After more than 3 years of actual use, no corrosion phenomena have been observed, proving their market acceptance.

Endure®cleanroom panels are a high-performance solution for pharmaceutical cleanroom wall panels that require VHP resistance. Their superior chemical resistance, wear resistance, and ease of processing make them an ideal choice for B-zone cleanrooms in the pharmaceutical industry.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.