We have a passion for unconventional solutions that bring your vision to life.

A cleanroom (also known as a dust-free workshop, dust-free room, or clean room) is a controlled environment with stringent requirements for air temperature, humidity, pressure, and particularly dust concentration. Cleanrooms can be categorized into industrial cleanrooms and biological cleanrooms based on their intended use.

Industrial cleanrooms primarily focus on controlling particles and are typically employed in the production of microelectronic products, precision machining, electronic components and assembly of certain electronic products, fine chemicals, and precision instruments and meters. Biological cleanrooms, on the other hand, concentrate on controlling airborne microorganisms and are commonly used in pharmaceutical production, hospital operating rooms, and biological safety laboratories.

The construction of a cleanroom is a complex undertaking that must adhere to both architectural standards and stringent controlled environment requirements while also accommodating production and operational process demands. Consequently, specialized expertise in cleanroom technology is essential throughout the entire process, from design to construction and operation.

Specialized aspects of cleanroom construction include:

Refrigeration

Air conditioning

Air purification and ventilation engineering

Cleanroom enclosure structure engineering

Air and environmental system commissioning and testing

Electrical engineering

Water treatment engineering

Gas engineering

Piping engineering

Even the most fundamental construction aspects can differ significantly in a cleanroom setting. Consider cleanroom enclosure structure engineering. Unlike conventional enclosures, cleanroom structures must not only meet the criteria of being non-dust-generating, non-dust-accumulating, and easy to clean but also employ appropriate materials based on the specific controlled environment. For instance, in a pharmaceutical B-grade zone where VHP disinfection is required, a special developed cleanroom panel -Endure® by Wiskind should be used.

The construction of a cleanroom necessitates meticulous planning, specialized expertise, and rigorous adherence to stringent standards to create a controlled environment that meets the precise requirements of the intended application.

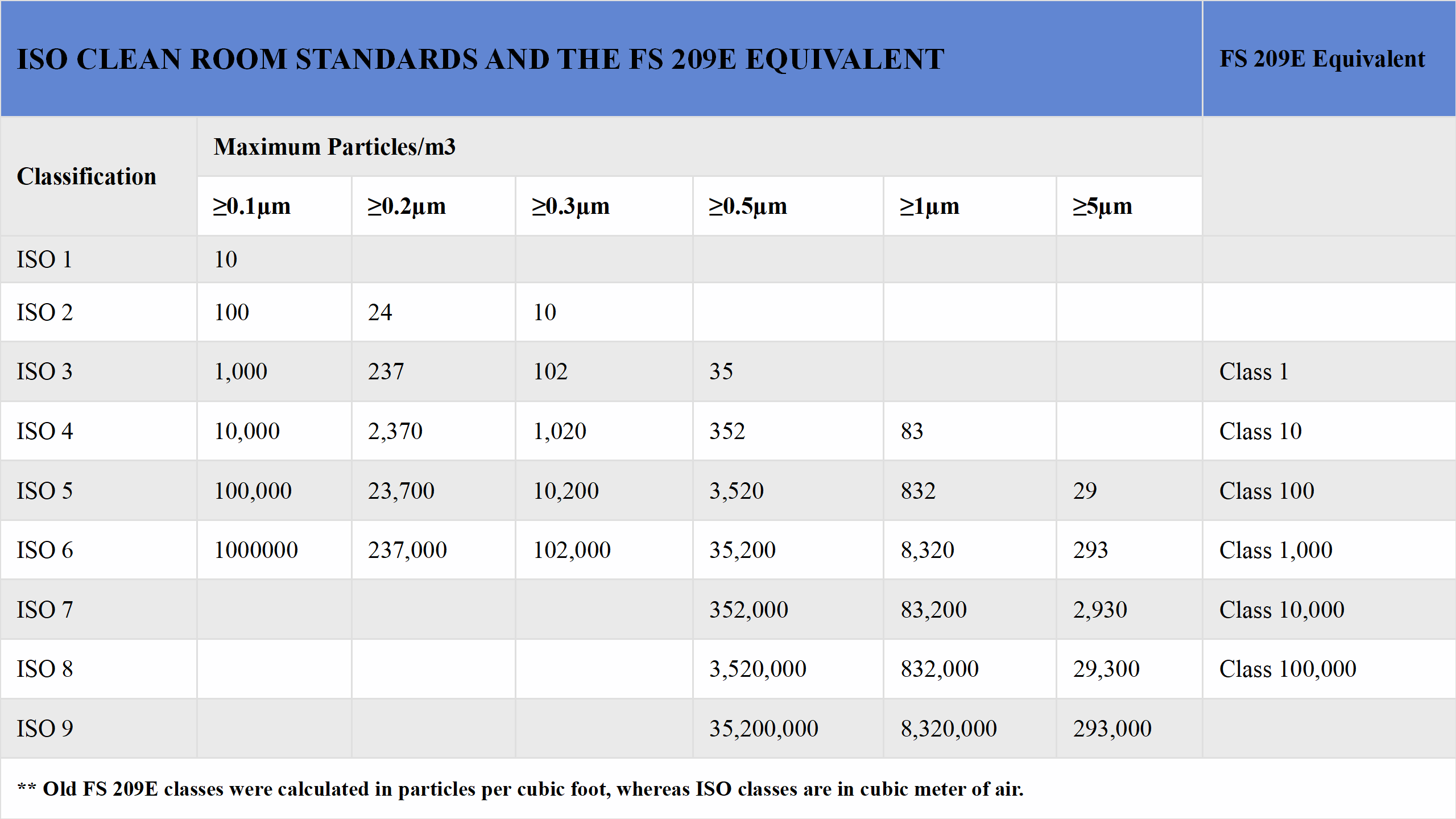

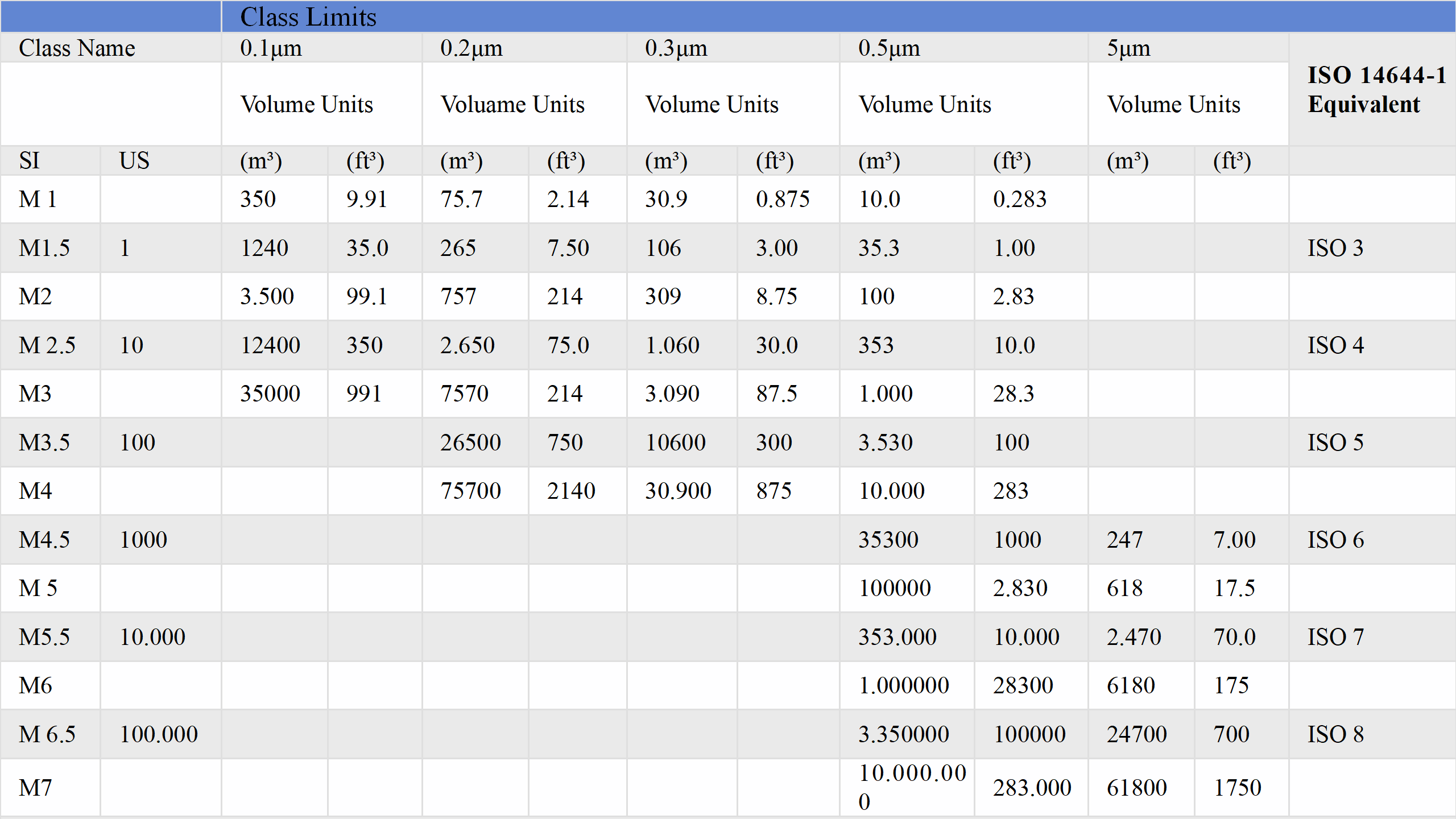

Cleanrooms are classified according to the number and size of airborne particles permitted per cubic unit of air. The most widely used classification system for cleanroom cleanliness levels is based on ISO 14644, "Cleanrooms and associated controlled environments." This standard classifies cleanroom levels into ISO 1 to 9 grades based on the concentration of particles of different sizes per unit volume. A smaller number indicates stricter control over the number of particles of a specified size per unit area, and therefore a higher level of cleanliness.

US Fed. Standard 209E was officially cancelled by the General Services Administration of the US Dept. of Commerce November 29, 2001, but is still widely used.

Cleanroom Classification Levels: ISO 14644 vs. USA Federal Standard 209E

In addition to the ISO 1-9 classification system, you may also encounter cleanroom classification levels such as "Level 10" or "Level 100." These classification levels are based on the US Federal Standard 209E (which is now obsolete). The key difference between the 209E classification system and the ISO 14644 system is the unit of measurement for particle concentration:

ISO 14644 classifies cleanrooms from ISO 1 (most clean) to ISO 9 (least clean). The number of particles per cubic meter of air allowed in each class decreases as the number increases.

US Federal Standard 209E classifies cleanrooms from Class 1 (most clean) to Class 100,000 (least clean). The number of particles per cubic foot of air allowed in each class decreases as the number increases.

Wiskind, established in 1978, is a leading provider of comprehensive cleanroom systems solutions. With over 40 years of experience, we design, manufacture, install, and service cleanrooms for a variety of industries including bio-pharmaceutical, electronics, food, semiconductor and new energy.

We offer one-stop service and a complete product portfolio including Cleanroom wall panels, doors,windows and more– all certified to meet the most stringent international standards (FM, CE, SGS, ISO9001, ISO14001). Our commitment to innovation and exceptional customer service has made us a trusted partner for clients around the world, with a presence in over 50 countries and regions.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.