We have a passion for unconventional solutions that bring your vision to life.

Reason:

1. In terms of raw materials: the wax paper on the surface of the steel door after spraying is too high.

2. Personnel: During the window installation process, the strength of the installed window was not checked, and the bonding strength between the glue and the surface of the door leaf was not checked.

3.Management: There was no strict verification of bonding strength during window installation. Instead, employees were simply asked to wipe the window with acetone, but the bonding properties of the window after gluing were not checked.

Solution:

1. Communicate with the spraying manufacturer about the thickness standard requirements of our door leaf spraying wax paper.

2. When installing a frosted door window, use foaming agent to fix the window and apply glue. After the window is installed, the glue will dry and do a window pressure test (squeeze the glass surface with your hands to see if the glass can move).

3. During the installation process of the door leaf and window after spraying, you can do a small test first, use sealant to make a window to check the adhesion test.

4. After padding it with iron sheet, fix it with foaming agent. Redefine the craft card for Windows installation

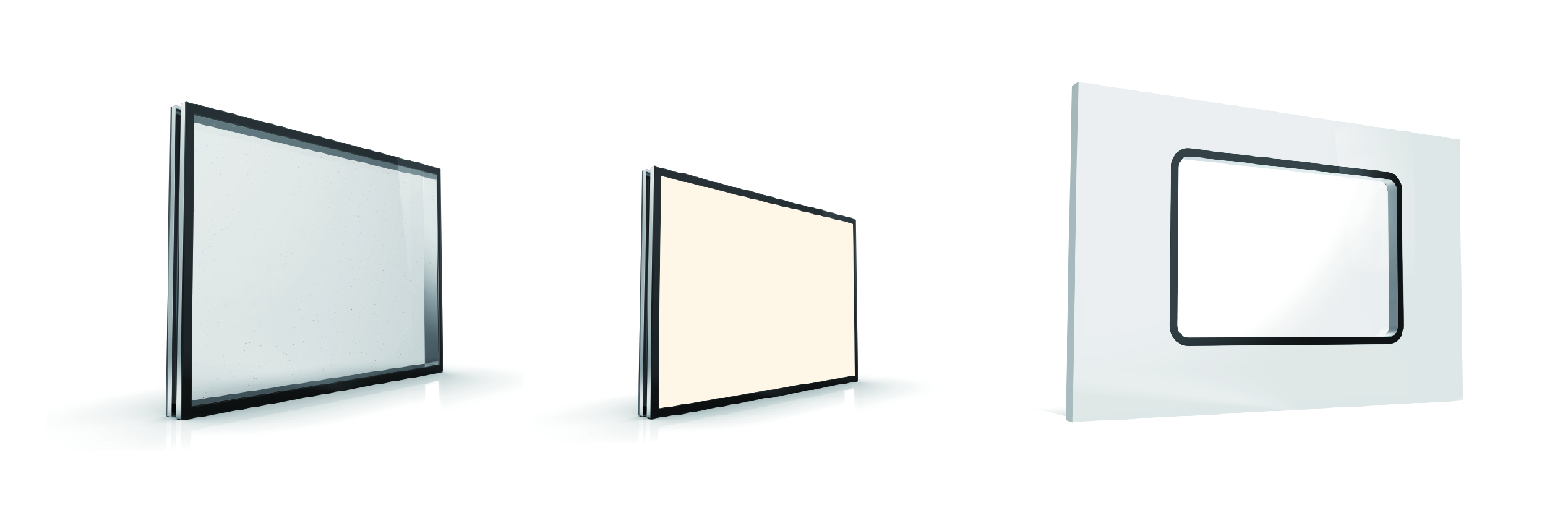

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.