We have a passion for unconventional solutions that bring your vision to life.

Cause:

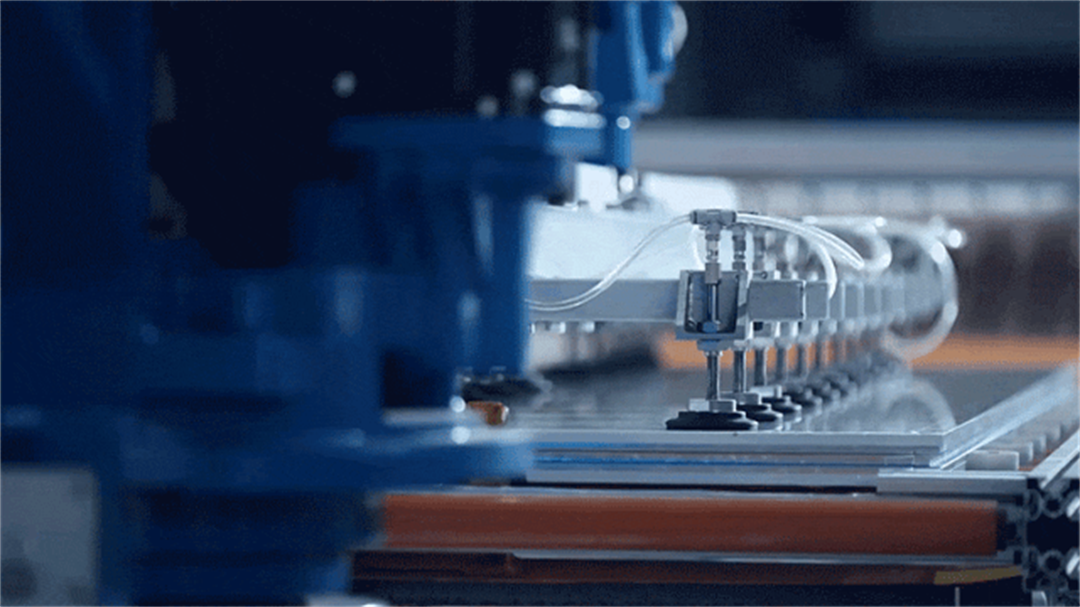

1. At present, the glue spraying process cannot handle the situation of emergency stop and move when the vertical edge is encountered. The uninterrupted glue spraying will cause glue to enter.

2. In order to ensure the molding angle of the cleanroom panel, the edge protective film breaks during molding.

Management:

1. There are no expected problems that may occur in the production of new processes and they are foreseen, and there are no relevant measures.

2. When problems were discovered during the audit process, no attention was paid to product quality.

Solution:

1. For hot-pressed production panels, buckle strips are used to protect the panels after loading.

2. After laminating the panels, do not wipe the end glue to prevent the glue from immersing.

3. Investigate possible hidden dangers and problems in the hot pressing production line, formulate measures and prevent problems.

4. When clearing the panel, focus on cleaning the end parts of the door headpanel, window upper and lower window panels. Clean the glue after the finished product comes out of the hot press.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.