We have a passion for unconventional solutions that bring your vision to life.

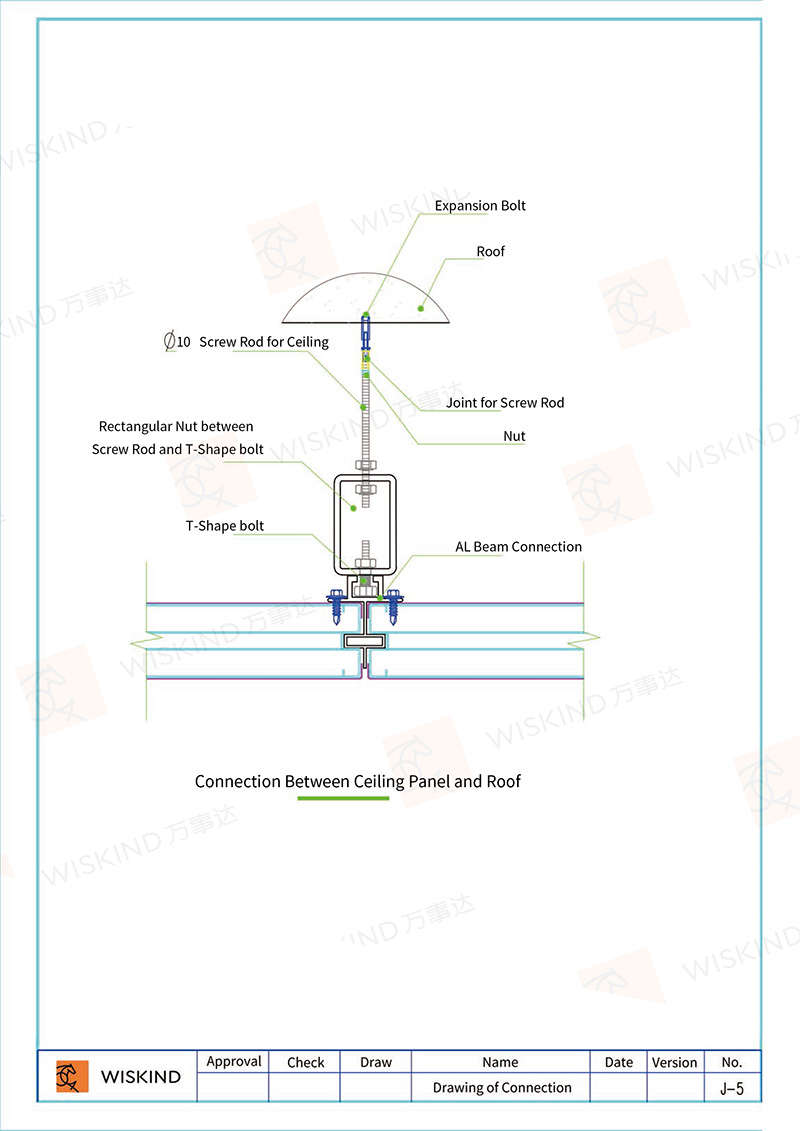

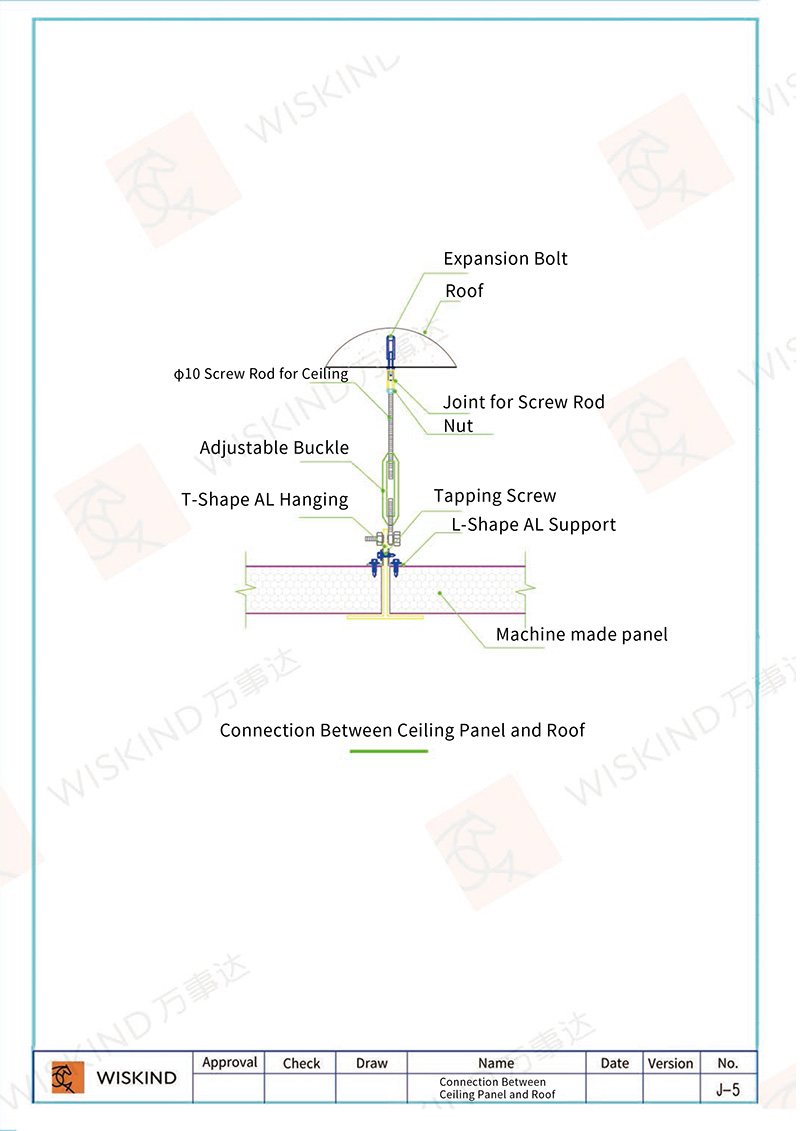

1、In the installation of clean room panel, should first according to the secondary design layout diagram to determine the hanging beam (t-beam, aluminum hanging beam, etc.), hanging parts, fixed points, anchoring parts and other three-dimensional components and roof beam link fixed position.Common hanging beam is divided into: civil beam, steel structure purlin link node as follows:

1、During the installation, the fixed point position shall be determined by setting off line with the horizontal instrument and marking it. Then, the spreader shall be installed. The spreader spacing shall be arranged every 1.2m, and the spreader shall be vertically horizontal.The roof beam is fixed with 10mm internal wire expansion screw, the other end of the lifting bar is connected with galvanized flower orchid bolt and special lifting beam or lifting piece, so as to adjust the flatness of the roof plate.

2、4 lifting points shall be arranged on the ceiling of the clean room every 2.4㎡, in the form of flower basket bolt hook, and ensure that the ceiling is straight after the load, and close to the arc.

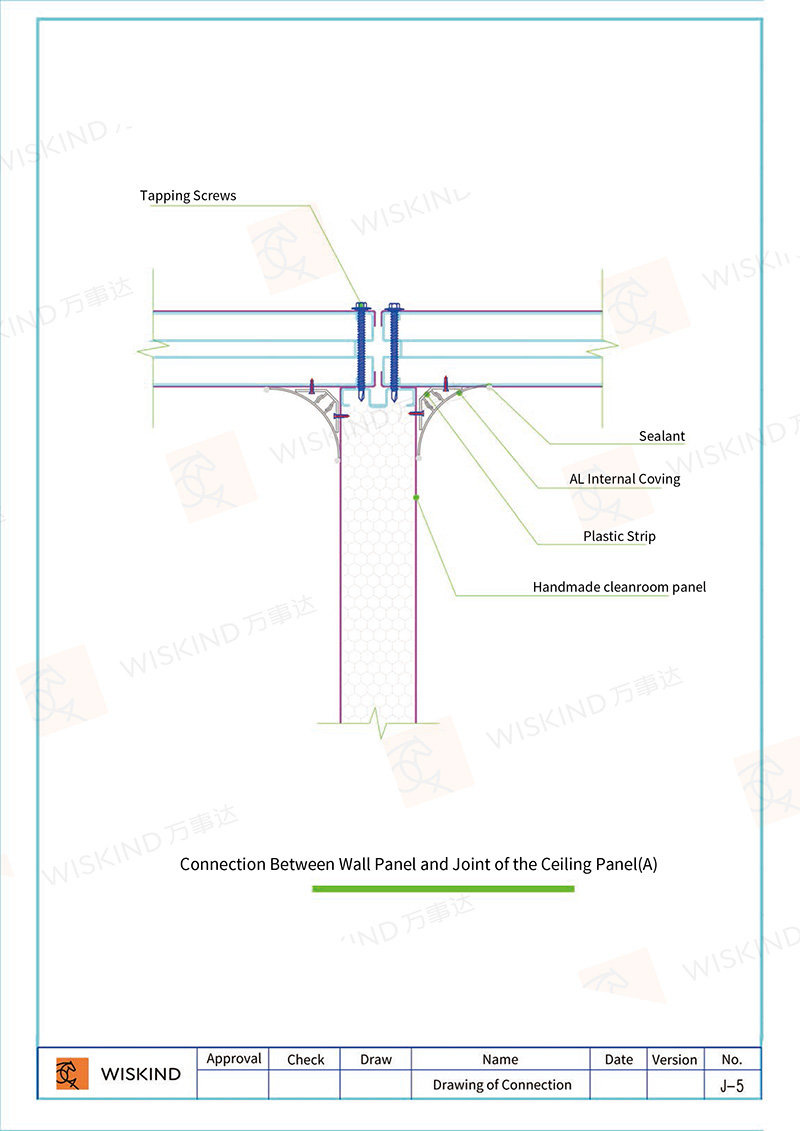

3、Clean roof presses room trend to undertake installation, its aperture should maintain in 2-3mm inside, roof every lie between 0.5m with rivet and dark condole girder is connected, make the connection between each other is firm.

4、When the length of clean room ceiling panel is larger than 3m, except for the dark hanging girder in the width direction, the length direction should be strengthened, using special C steel to strengthen the hanging beam and roof keel connected with dovetail screw, and then using through wire suspender to hang tight.

5、clean room ceiling construction, other types of work on the roof construction to make good protection measures, strictly prohibit large-scale construction on the ceiling.

1) the tensile strength of lifting tools such as rope, hook and pulley must be at least 3 times of the plate's dead weight (PU 40kg/ m3, glass wool 64kg/ m3, rock wool 120kg/ m3).

2)Cleanroom wall panel protective film can be removed after the completion of the project, the rest of the board can be directly removed before installation, when the core material has rock wool or glass wool, can be used as temporary waterproof protective film.

3)The protection of the outer plate shall be given priority during the stacking of the plate.

4) the production of clean room wall panel shall be carried out in strict accordance with the size designed on the drawing, and the production error shall be controlled within 0~+1mm.

5) pay attention to whether the surface of the clean room panel meets the requirements during production.Surface without scratch, collision, paint, and other phenomena.

6) during the installation process, clean room panel shall be installed in strict accordance with the design and construction drawings to ensure proper registration.

7) before installation, please check whether the length model of wallboard is in line with the design drawing. If the allowable error is exceeded, it shall be removed and not put on the wall.

8) protection of finished products;Already went up the clean room panel of the wall should do well to protect work more, avoid to cause bigger loss.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.