We have a passion for unconventional solutions that bring your vision to life.

A. Clean room wall panels installation should be carefully according to the construction drawing line.The corner shall be vertically connected to prevent the wall panel from tilting and twisting. The clean room sandwich panels perpendicularity deviation shall not be greater than 0.15%.

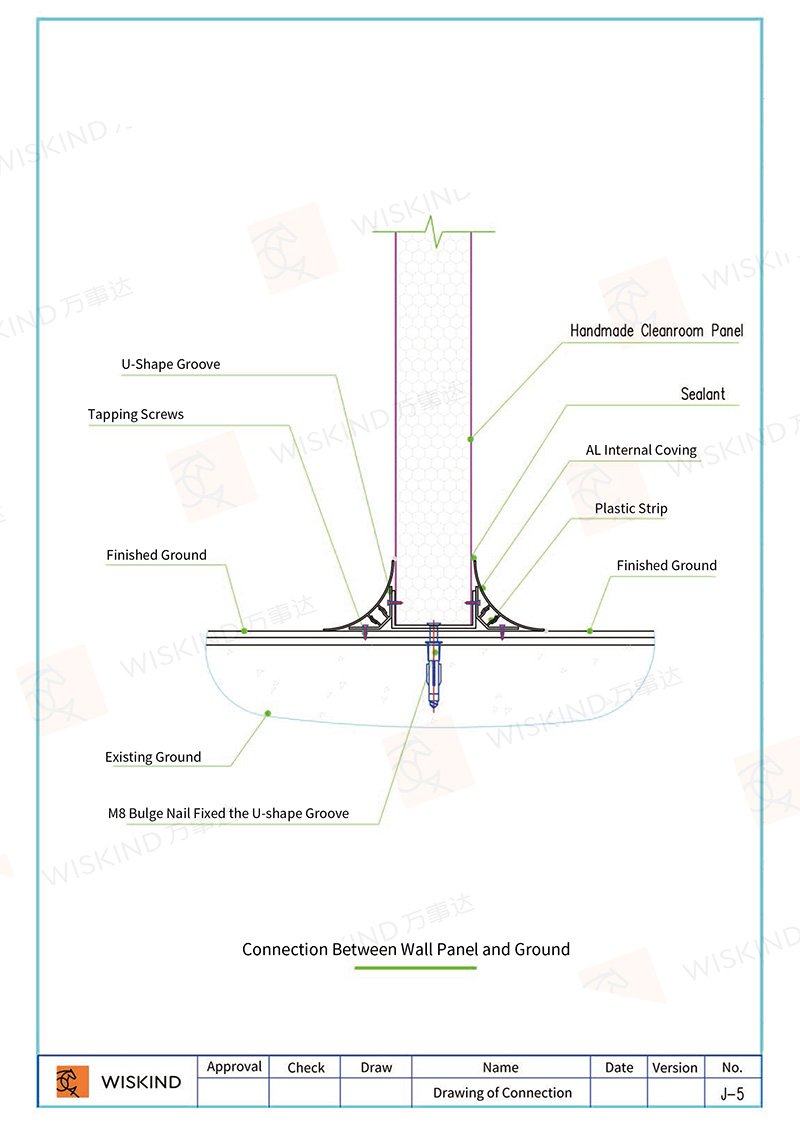

B. Clean the ground and install U slot in the base with the same horizontal size as the line setting, and fix it with M8 expansion bolts with 500mm spacing between the bolts.(node is shown below)

C. After the installation of the Biological clean room wall panel, the seam gap shall be consistent, and the gap error of each panel shall not be greater than 2mm, and the positive pressure surface shall be uniformly sealed with sealant, which shall be flat and smooth, slightly lower than the plate surface, without any discontinuity or impurities.

D. The electrical junction box on the wall panel, the control panel and the various openings where the pipeline passes through should be located correctly, with neat edges, tight, clean, dust-free and sealed with non-combustible or non-combustible materials.

E. The reserved hole for installing clean room doors and Windows should meet the design requirements, and should be smooth, tight, clean and dust-free.

F. The partition plate shall be installed firmly, and the position, quantity, specification, connection method and anti-static method of embedded parts and connecting parts shall meet the design requirements.

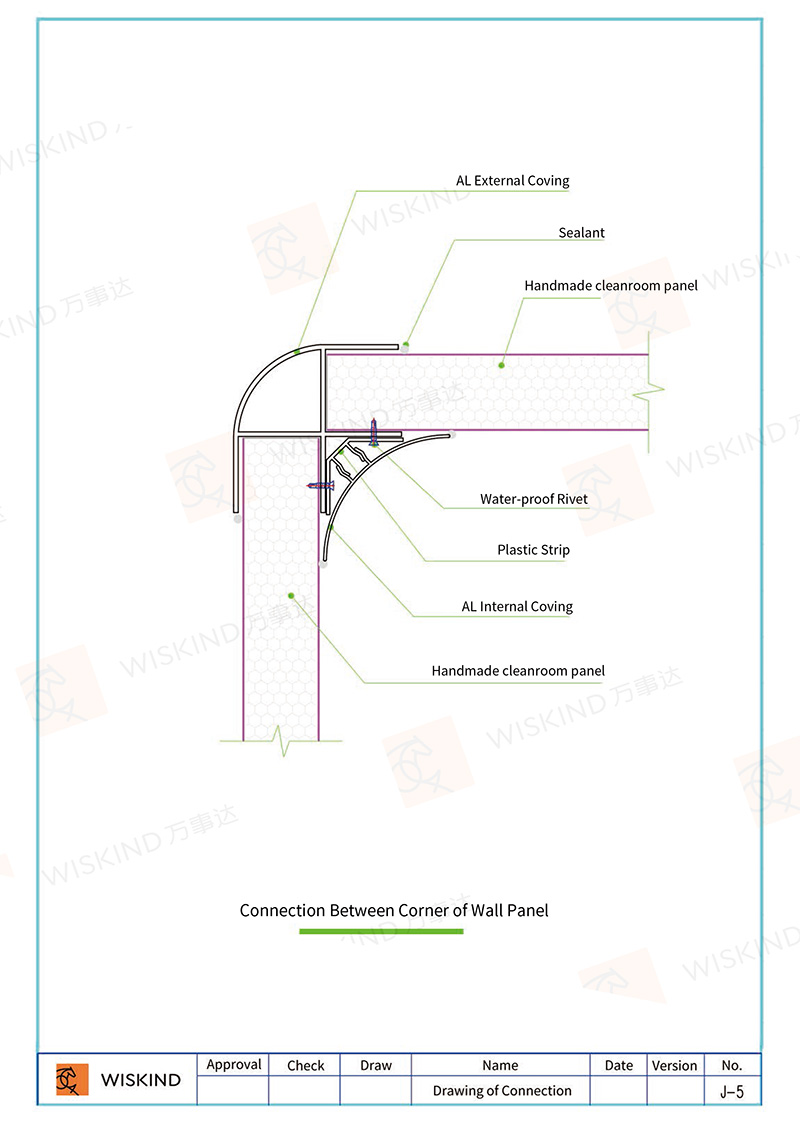

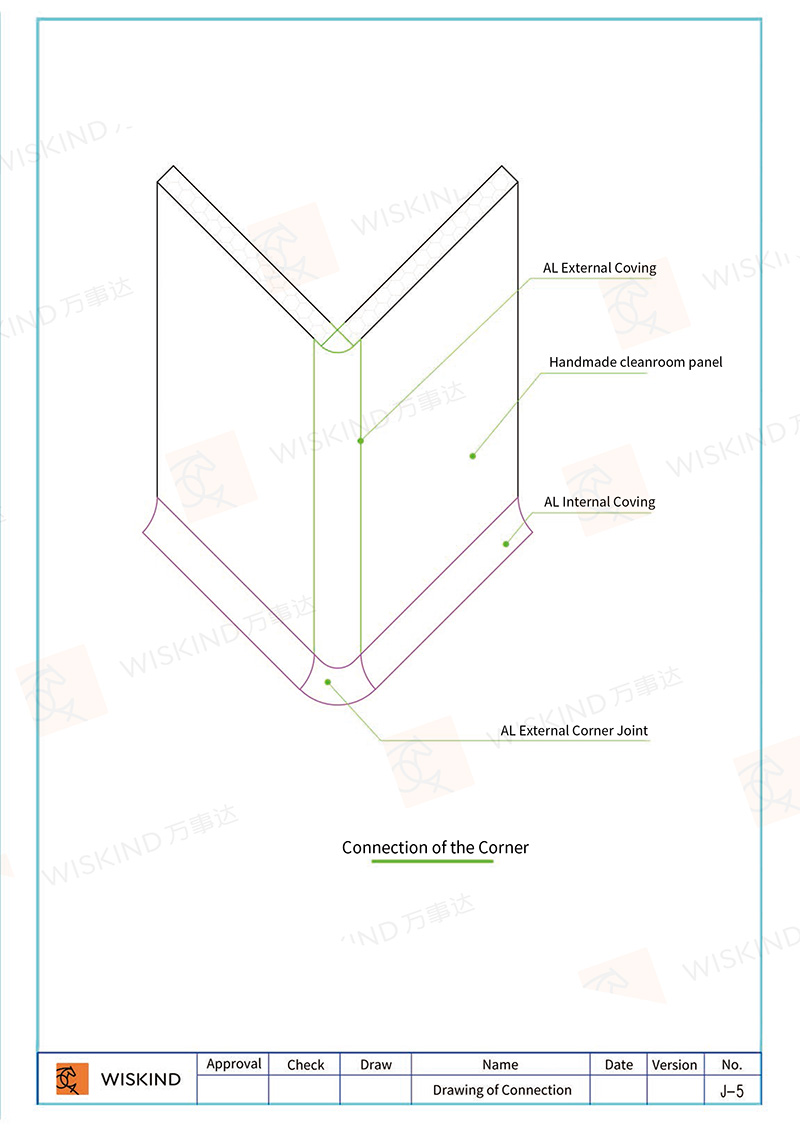

G. The wall surface plate shall be installed vertically, flat and in the right position. Anti-cracking measures shall be taken at the junction with the ceiling plate and the relevant wall plate.The joints shall be sealed.Round corners should be used.(node is shown below)

H. The surface of the wall should be smooth, smooth and consistent in color. The mask of the wall panel should be intact (before tearing the film).

I. The allowable deviation and inspection method for wall plate installation shall conform to the requirements in the following table.

Allowable deviation and inspection method for wall plate installation.

No. | Project | Allowable deviation(㎜) | Inspection methods | |

Metal sandwich plate | Other composite plates | (Not limited to the following methods) | ||

| 1 | Elevation perpendicularity | ≤1.5 | 2.0 | Check with 2m vertical test ruler |

| 2 | Surface flatness | ≤1.5 | 2.0 | Check with 2m gauge and feeler |

| 3 | Seam difference | 1.0 | 1.5 | Check with steel ruler and feeler |

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.