We have a passion for unconventional solutions that bring your vision to life.

1.Familiar with the clean room drawings, carefully review the layout of the cleanroom panel, node requirements, the relationship between the cleanroom panel and the building, the color, filling, and basic size requirements of the cleanroom sandwich panel itself, and the size and layout of cleanroom doors and windows in the clean room partition. Types of auxiliary materials and other contents.

2.When prefabricating in a clean room factory, based on experience, fully consider the clearance and installation allowance between door openings, window openings and seams. And during the entire transportation, production, and installation process, prevent scratches, heavy pressure and surface impact to prevent uncorrectable pits and scratches. The protective films on both sides of the cleanroom sandwich panel are only allowed to be removed after the installation is complete and thorough cleaning is performed.

3.The laying-out work before the installation of the cleanroom sandwich panel should be carried out after the ground (floor) surface is completed, and other relevant conditions for installation, such as larger equipment has been transported in place, the underground pipeline has been adjusted, and the main technical sandwich panel has been adjusted. The installation work is basically completed before proceeding. Pay-off is to mark the horizontal projection of the cleanroom panel (50mm wide) and the position of cleanroom doors and windows on the ground. The center lines of the upper and lower mangers should be on the same vertical plane and the error should be within 1.0%, which is 3mm.

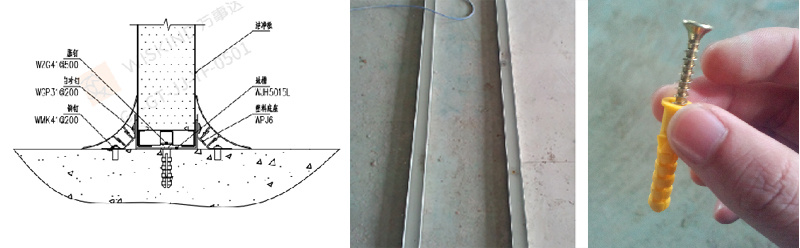

4.Install the ground rail and fix it on the line drawn on the ground with the expansion plug. The position of the expansion plug should be 1.2-1.5m in a straight line, and the corners and terminals should be 0.2m away from the side. After the expansion plug is fixed, a waterproof isolation groove is formed. The cleanroom sandwich pane is placed on the adjustable floor cabinet, and the wall panel and the wall panel are connected with aluminum profiles.

5.When installing cleanroom wall panels, it is worth paying special attention to the installation of electric concealed pipelines and boxes. The wallboard should be vertical, the vertical seams should be tight, the gap should be kept at 3mm, and the vertical seams should be even. During operation, carefully clean up the debris in the board seam and the solidified hard blocks of the glue liquid.

6.Install the cleanroom ceiling panel. The weight support of the top panel is fixed and connected by the wall panels fixed on the periphery and the Z-shaped aluminum profile suspended in the middle. The ceiling panel strives to be flat, and the panel seams are dense and uniform, smooth, and non-marking. If the ceiling panel needs to be installed with air conditioners and air outlets, the load-bearing capacity of the ceiling panel should be considered to ensure that later personnel can stand up to perform equipment repairs and maintenance.

7.When installing a cleanroom door, pay attention to the opening direction. The door closer should adjust the opening speed and force. Generally, when closing the door, the first half of the speed is fast, the second half of the torque is small, and the speed is slow, so as to reduce the closing impact and noise.

8.Sealing silica gel: In the clean area, all gaps that may affect the cleanliness level should be coated with sealing silica: the splicing joints between the clean plates, all the gaps between the R angle and the wall plate and the top plate; air-conditioning ducts, air outlets , The gap between the high-efficiency filter and the top plate. The sealing silica gel should be installed on the clean board, and the sanitary conditions are good. After thorough cleaning and dust removal, the clean room is carried out uniformly. Otherwise, the silicone seam is easy to be polluted and blackened. Within 24 hours after the silica gel is finished, there should not be a lot of dust and water washing the ground, which may affect the curing and fastness of the sealing silica gel.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.