We have a passion for unconventional solutions that bring your vision to life.

In undertaking food factory reconstruction and technological transformation projects, waterproofing has always been a very troublesome and troublesome thing. Failure to do so has caused water seepage and water leakage to be more common, which affects the cleanroom level requirements. Imported, so the safety and hygiene of the food industry occupy an important position in our daily lives.

During the construction of the food cleanroom, if the waterproof problem is not dealt with properly, it will cause corrosion of the cleanroom panels surface, reduce the service life, and bring great inconvenience to future maintenance, construction period and compensation. Moreover, the cleanroom now requires waterproof quality More and more, the warranty period has also become longer and longer. Therefore, how to solve pollution and control problems has become a key link in the design.

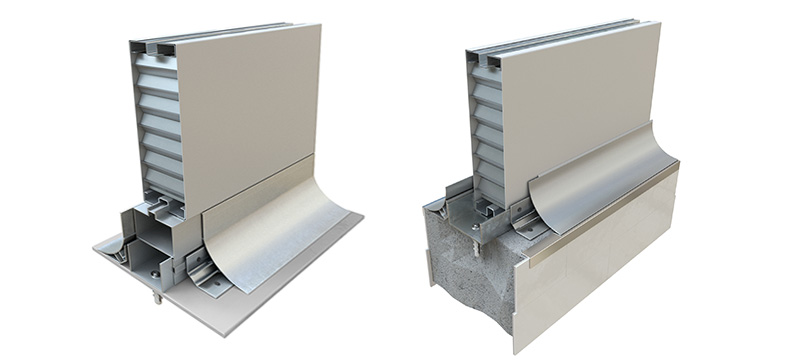

After more than 40 years of industry production and installation experience, Wiskind has designed 2 cleanroom waterproof nodes. During the installation of cleanroom panels, it prevents long-term use and water erosion, resulting in rusting of cleanroom panels.

Secondly, the floor of the food production workshop is constructed with non-slip, sturdy, impermeable, and corrosion-resistant materials, and is flat, free of stagnant water, and kept clean; the outlet of the workshop and the drainage and ventilation parts connected to the outside world are equipped with anti-rat, anti-fly, Anti-insect facilities. Workshop cleanroom panels, cleanroom ceiling panels and cleanroom doors and windows must be non-toxic, waterproof, mildew proof, non-shedding, and easy to clean.

The operating table, conveyor belt, transport vehicle, and tools in the workshop should be made of non-toxic, corrosion-resistant, non-rusting, easy to clean and disinfect, and strong materials. Sufficient hand-washing, disinfection, and hand-drying equipment or supplies should be installed in appropriate places, and the faucet should be non-manual switch. According to the needs of product processing, there should be disinfection facilities for shoes, boots and wheels at the entrance of the workshop. There should be a dressing room connected to the workshop. According to product processing needs, toilets and shower rooms connected to the workshop should also be set up.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.