We have a passion for unconventional solutions that bring your vision to life.

There are many types of cleanroom panels. Today we will give a simple understanding of cleanroom panels based on different core materials.

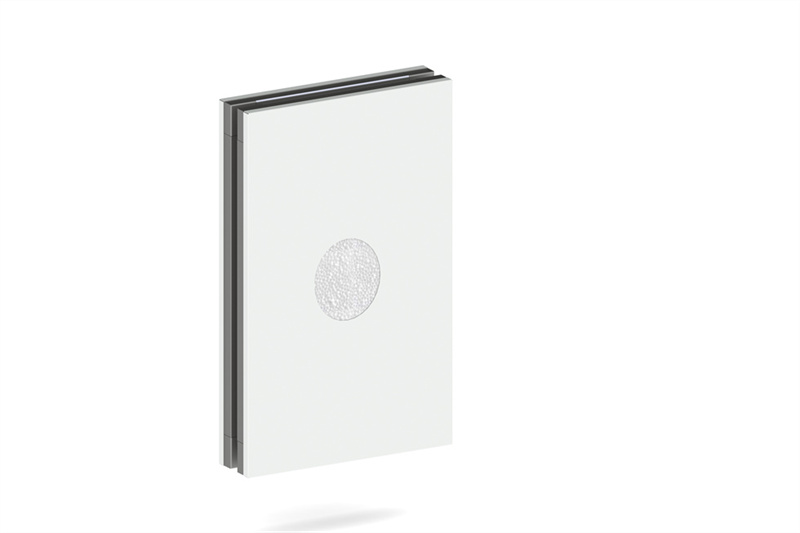

1. EPS panel

EPS is the foam panel we are familiar with. It has the advantages of light weight, low price, low thermal conductivity, low water absorption, good electrical insulation performance, sound insulation, shockproof, and moisture resistance. EPS panel is a kind of thermoplastic material, which contains 3-6 million independent closed air cells per cubic meter, and the volume of air contained is more than 98%. Because the thermal conductivity of air is very small and it is enclosed in foam plastic It cannot convect, so EPS is a material with very good thermal insulation performance.

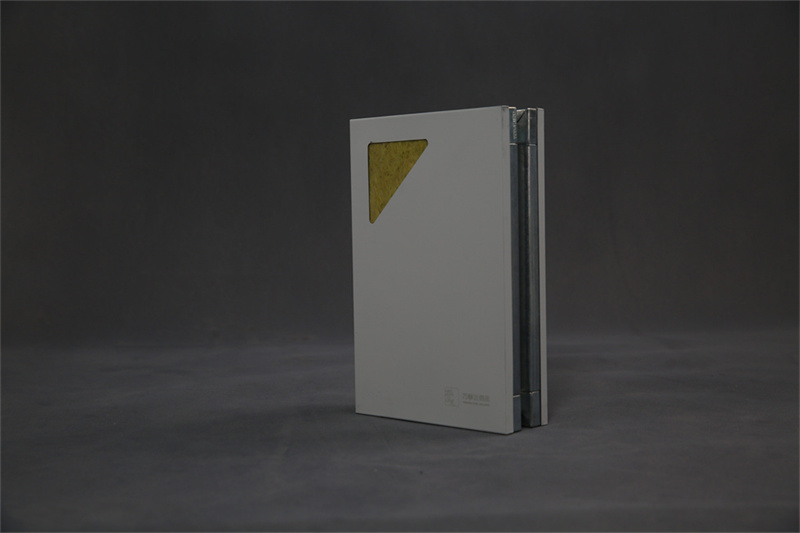

2. Rockwool

The rockwool sandwich panel uses color steel profiled panel as the surface layer, rock wool structure as the core layer, and is compounded with a special binder to form a "sandwich" structural panel. It belongs to the cleanroom panel with strong fireproof effect, which can be blocked on all sides, and reinforcing ribs are added in the middle of the panel to make the panel surface smoother and stronger.

Features: smooth and beautiful, the products include steel surface asbestos core panel, steel surface aluminum (paper) core panel, steel surface gypsum core panel, steel surface asbestos core panel, steel surface gypsum layer extrusion reinforced asbestos core panel. Special core materials and plates with special specifications can also be made according to customer requirements. Sound insulation, heat insulation, heat preservation, earthquake resistance and fire prevention performance are good. The filling materials of the product are all A-class flame retardant materials, which will not melt when burned, and there will be no pyrolysis drippings. It belongs to the domestic high-grade fireproof building decoration composite panel.

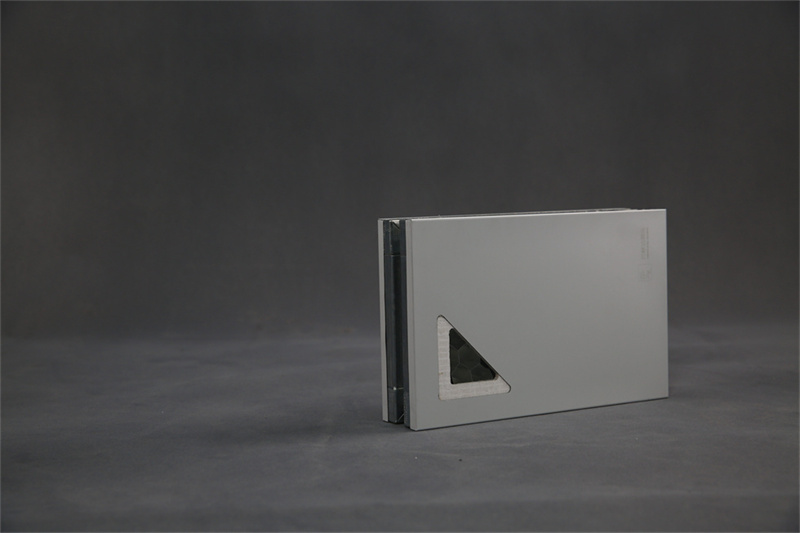

3. Aluminum honeycomb

Aluminum honeycomb sandwich panels can be made into light-weight, high-strength, rigid and very flat cleanroom panels, which can be used in structures such as curtain walls, buildings, partitions and decorations. The quality of fluorocarbon aluminum honeycomb panels such as partitions and sound-absorbing panels is not only related to the selected materials, but also mainly depends on the quality of adhesion, and the key technical indicator is peel strength.

Characteristics of aluminum honeycomb cleanroom panel

(1) Wide range of applications: products are used in clean room ceilings, factories, warehouses, refrigeration, air conditioning and walls.

(2) Product diversification: Products include rock wool cleanroom panels, silica rock cleanroom panels, honeycomb cleanroom panels, etc. There are various types of core and face materials.

(3) Good physical and chemical properties: The steel surface of the product is a high-grade polyester baking coating or zinc coating, so its corrosion resistance is particularly good, and the filling materials of the product are all Class A flame retardants. Ingredients that won't melt even if burned.

(4) Convenient construction and installation: with fixed length and width, it can be produced according to the buyer's project requirements, and can be combined and installed. It can greatly reduce the foundation and structural engineering costs of buildings, and can be disassembled many times, which is convenient for construction and installation. The comprehensive advantages are very important.

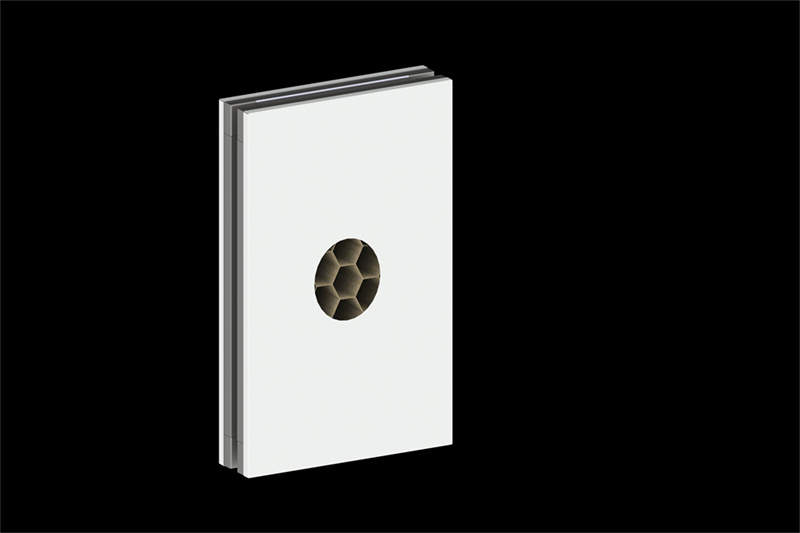

4. Paper honeycomb

The core of the paper honeycomb cleanroom panel is made of flame-retardant paper, and the panel and the other panel can be made of color steel panel and stainless steel panel. Its flame retardancy is B1 level (only carbonization is non-combustible), high rigidity, high strength, strong bearing capacity, good heat insulation and sound insulation, strong flame retardancy, and no toxic ingredients.

5. MGO panel

The characteristics of the MGO panel are as follows, and these advantages allow MGO panel to be used in the harsh environmental requirements of the purification project.

(1) The MGO panel has excellent resistance to high temperature, because it can be regarded as suppressive to fire, and it is for the sake of people's health and safety.

(2) The MGO panel has a certain effect of sound insulation and sound absorption. During the work and production, the noise generated in the workshop can be better controlled, and it is of great help to the staff to prepare more efficiently.

(3) Safety, environmental protection and pollution-free are the green features of the MGO panel. In the sealed environment of the purification project, workers work for a long time. Of course, they must choose safe and green building materials. The MGO panel is a very environmentally friendly panel. , no harm to human body.

(4) The MGO panel is very convenient to assemble. Whether it is nailed or pasted, it is one of the assembly methods of the MGO panel. Moreover, it has strong flexibility, is not easy to break, and has a beautiful appearance. Create a safe and comfortable working environment for people.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.