We have a passion for unconventional solutions that bring your vision to life.

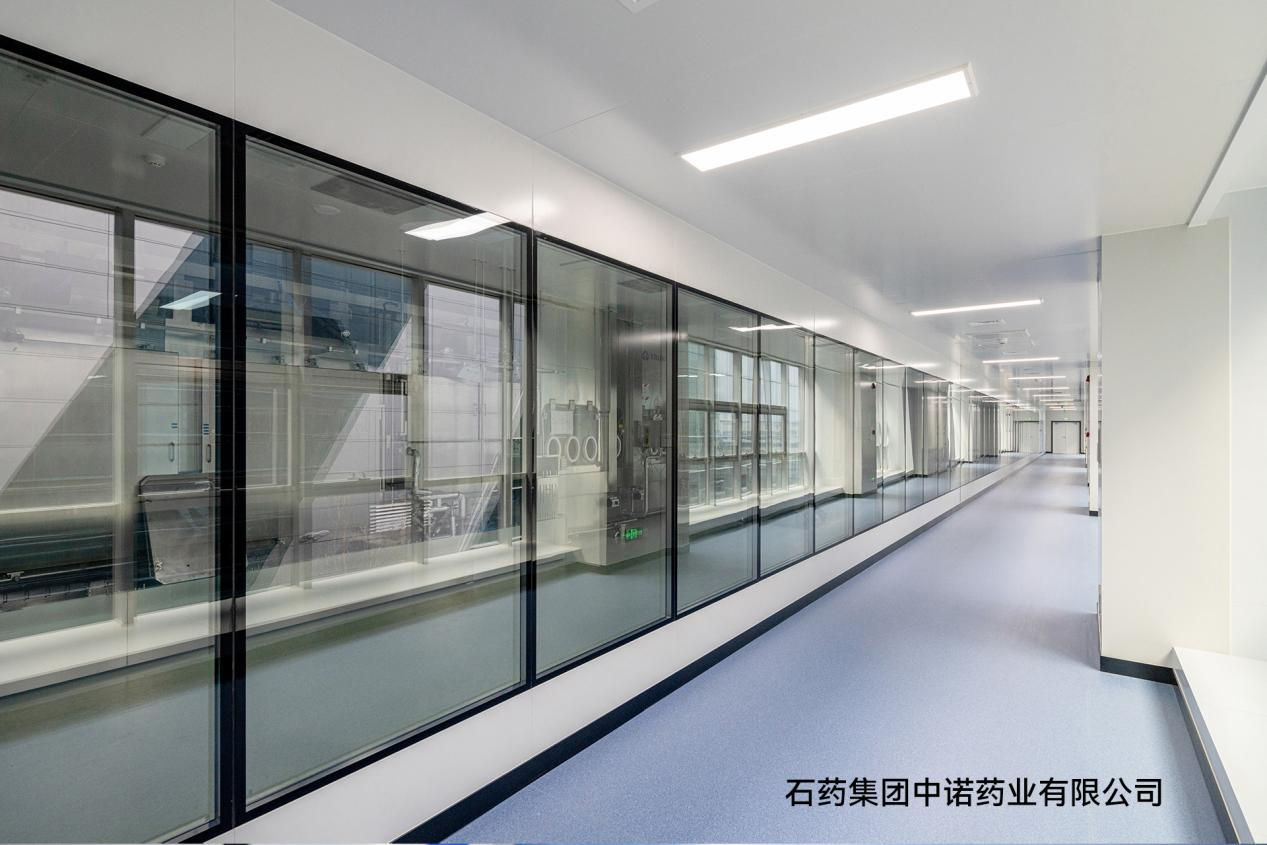

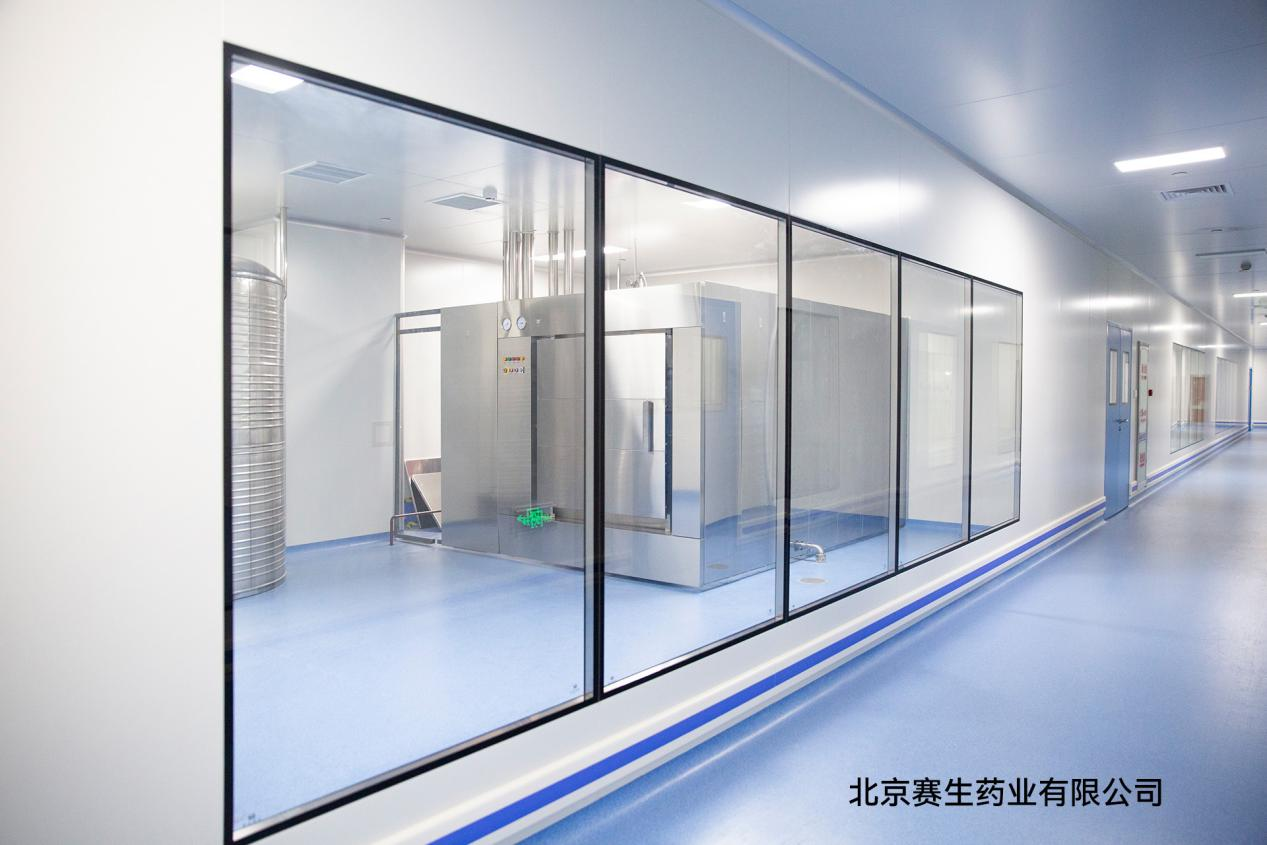

Fogging on the interior of double-glazed windows in pharmaceutical cleanrooms has long been a headache for the industry. This is particularly problematic in cleanroom visitation corridors, where fog can significantly impair the visitor experience. While fogging may not directly impact production operations, it remains a constant source of frustration for facility owners. Prior to installing double-glazed windows, pharmaceutical companies lacked effective inspection methods to ensure airtightness, often leading to the discovery of problems after installation that were difficult to rectify.

Causes and Impacts of Fogging

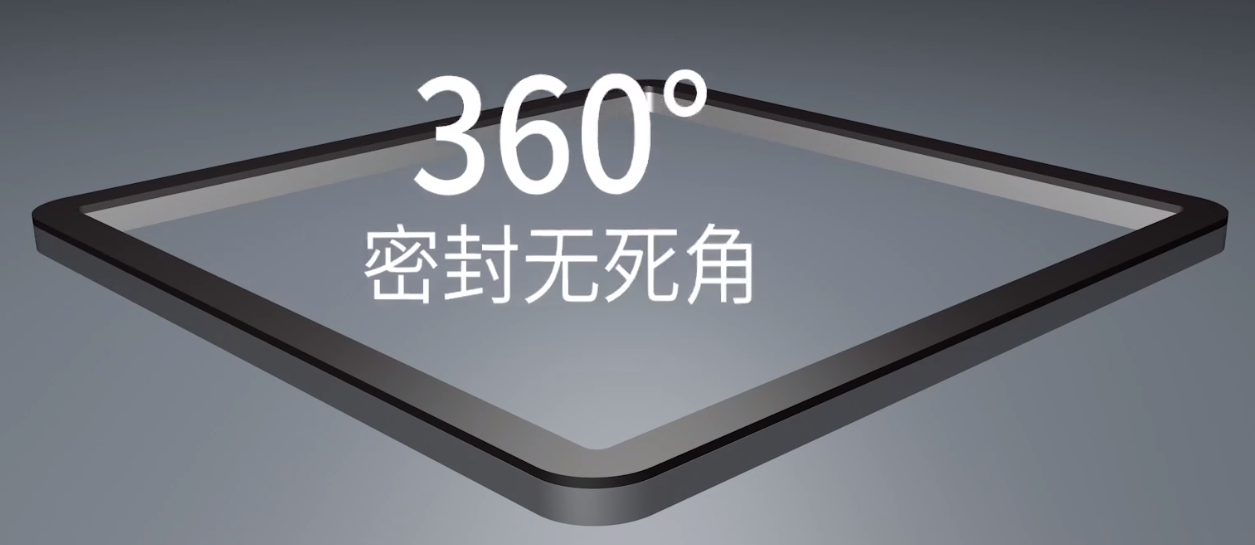

The primary causes of internal fogging are product structural issues and process-related problems. These factors result in poor airtightness of the double-glazed window after installation, allowing moisture to enter and cause fogging. Condensation of moisture inside the window not only hinders cleaning but can also lead to microbial growth and corrosion over time, increasing the risk of contamination during drug production.

Solutions for Fog-Free Cleanroom Windows

To address this industry challenge, Wiskind Cleanroom Windows offers a highly effective solution for preventing fogging, leveraging its exceptional manufacturing processes and stringent quality control.

Production in a Controlled Environment

Wiskind produces its windows in a dry, clean, and controlled environment, preventing moisture intrusion from the outset.

Incorporation of 3A Molecular Sieves

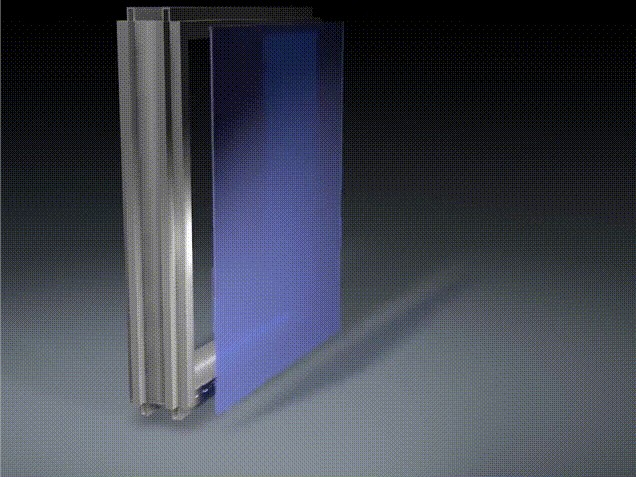

3A molecular sieves are materials used for adsorbing and separating molecules. Due to their excellent adsorption capacity and selectivity, Wiskind fills the window frames with 3A molecular sieves as a desiccant. Unlike competitors who only fill one side of the frame, this approach achieves superior drying performance.

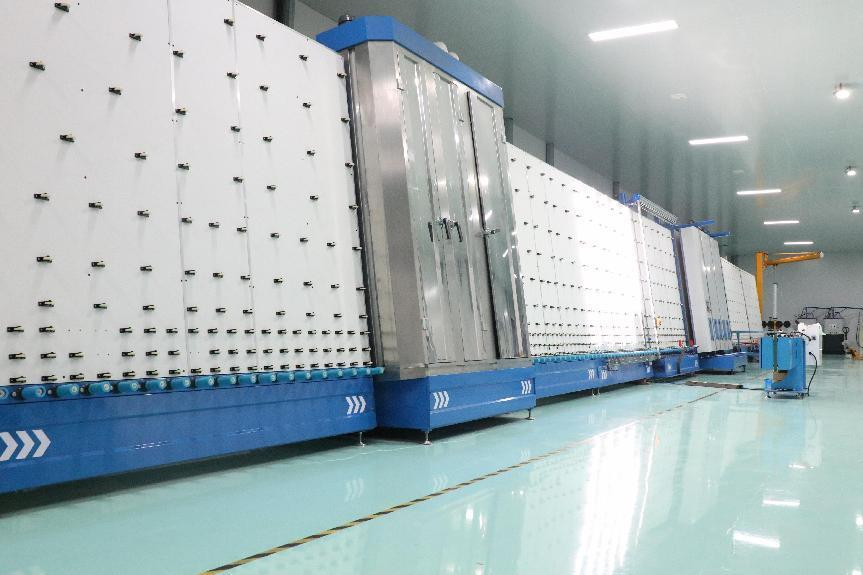

Automated Production Equipment

Wiskind's automated cleanroom window production line, featuring Italian equipment with secondary in-house development, enables fully automated production, revolutionizing traditional manufacturing processes. The entire line consists of automated cleaning and drying systems, high-definition raw material inspection systems, intelligent lamination systems, and automated gluing systems, with a smart control system connecting all stages. By integrating with a digital manufacturing system, the cleanroom window product supply chain achieves end-to-end process coordination, significantly improving product supply efficiency.

Strict Material Selection and Structural Design

Wiskind's cleanroom windows also demonstrate expertise and rigor in material selection and structural design. By using butyl rubber, which offers significant advantages, to seal between the frame and glass, Wiskind ensures long-term airtightness. Butyl rubber, with its excellent aging resistance and weatherability, guarantees the stability of the window under various temperature and humidity conditions, preventing external environmental intrusion into the cleanroom. During installation, a two-component neutral silicone sealant is used to further ensure the window's airtightness and structural strength. This sealant exhibits excellent adhesion and durability, providing strong physical and chemical support for the cleanroom window and ensuring its reliability during long-term use.

Proper Installation to Ensure Airtightness

Moreover, Wiskind recognizes the importance of adhering to operational standards during installation to maintain the window's airtightness. Therefore, the company provides detailed installation guidelines for cleanroom enclosure structures, ensuring that contractors can complete the installation to the highest standards and avoid damage to the frame or loss of airtightness due to improper operation. This not only guarantees the optimal performance of the window product but also ensures the aesthetics, durability, and practicality of the entire cleanroom.

High Delivery Standards, Setting New Industry Benchmarks

Wiskind has already invested in and operated two fully automated digital cleanroom window production lines with 3 Cleanroom panels manufacturing base, which are of strategic significance for Wiskind to accelerate its worldwide market layout and establish efficient supply response system. At the same time, this has brought new development momentum to the industry by establishing high-quality product standards and highly efficient supply cycles.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.