We have a passion for unconventional solutions that bring your vision to life.

Pharmaceutical cleanrooms present unique challenges for layout design due to their intricate internal compartments and varying requirements for different zones. As a result, manual layout of cleanroom wall panels is often time-consuming and prone to errors.

Issues with Manual Layout

Currently, manual layout heavily relies on 2D CAD software. Engineers must optimize designs based on drawings and site conditions, manually annotate and number each panel, and input material quantities. Despite advanced hardware, the daily work remains dominated by repetitive counting tasks.

Human involvement introduces significant risks. Each engineer's attention to detail, understanding of drawings, and cost-saving measures can vary. Additionally, managing multiple projects can lead to fatigue and errors. How can we ensure that junior designers achieve the same level of efficiency and cost-consciousness as senior designers? How can we prevent dimensional errors that can delay construction and waste materials? These questions demand in-depth consideration and solutions.

Wiskind CleanCube: Automated Layout Software

Wiskind's CleanCube intelligent design software offers a paradigm shift from manual to automated layout. This platform represents a significant breakthrough in cleanroom design, integrating flexible intelligent manufacturing and digital delivery processes to achieve standardized construction with low costs and high efficiency. CleanCube streamlines the management of cleanroom projects, promoting standardization and engineering, and providing strong support for the industry's advancement.

30% Increase in Design Efficiency

CleanCube liberates designers from repetitive tasks, replacing manual counting with digital intelligence for greater speed and accuracy.

Precise Quantity Calculation and Cost Savings

With CleanCube, material and auxiliary material quantity lists can be exported with a single click, ensuring accurate quantity calculation for both initial budgeting and subsequent implementation. This enables better control over material usage and cost transparency.

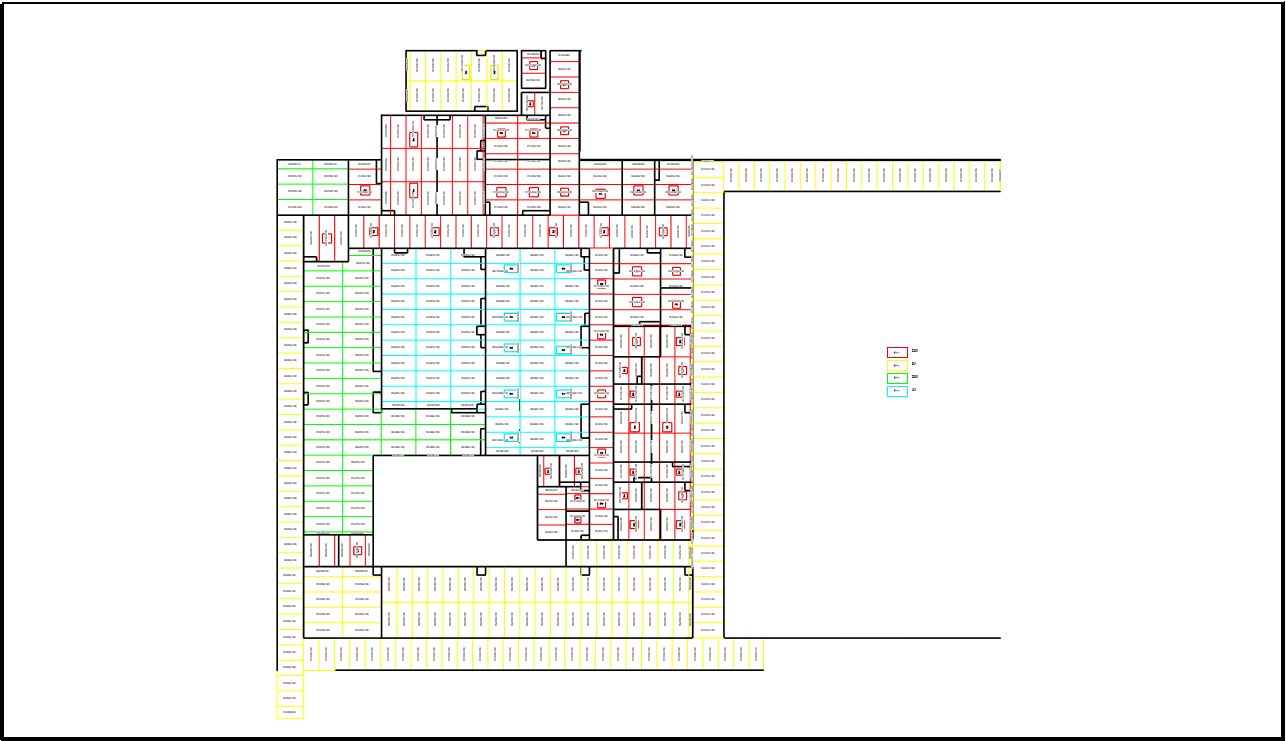

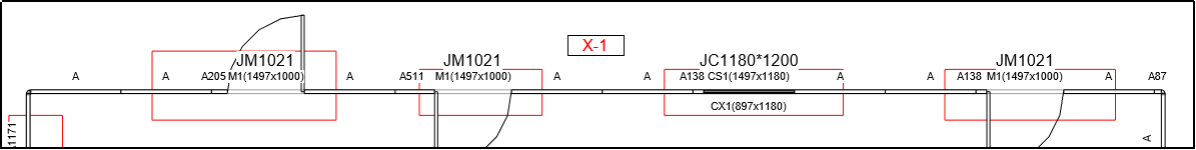

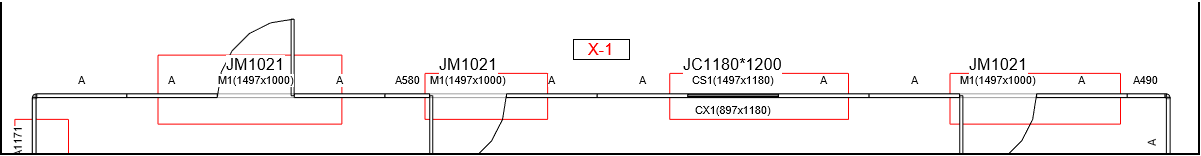

More Standardized Drawings

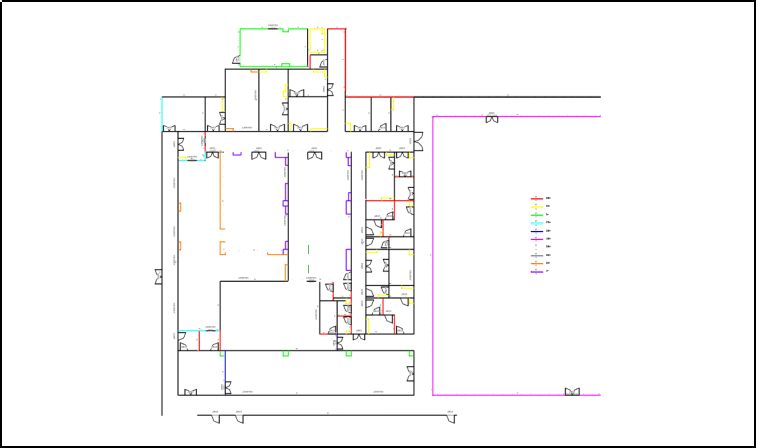

CleanCube can distinguish different information, such as height, coating, and core material, using various colors based on project and site requirements. The drawings are clear, concise, and easy to understand. Different coding methods cater to the viewing and construction habits of various personnel, maximizing construction efficiency.

CleanCube - Automatic Cleanroom Design Layout software

Further Improved Construction Efficiency

By introducing a non-standard size optimization logic, the system automatically calculates and optimizes non-standard dimensions. Compared to traditional manual layout, non-standard specifications are reduced by 40% (based on a 5,500 square meter wall panel project). At the same time, it standardizes the output quality of technical personnel, minimizing the difficulty of finding and installing panels on-site, and significantly improving installation speed.

Practical Application and Verification

CleanCube is currently available for trial and has been successfully applied in projects such as Qilu Pharmaceutical and Genscript. It has significantly improved efficiency and reduced costs for our customers.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.