How to choose air return systems in pharmaceutical cleanrooms has always been a crucial thing, since it is required to achieve both high purification and energy savings. Wiskind Hollow return air system is engineered to meet the high standards of pharamceutical cleanrooms. Regarding the classification of cleanrooms, whether it's the standard of ISO 1-9 or the industry-common terms of Class 100, Class 1000 (old US federal standards), or even industry-specific standards (like the pharmaceutical industry's A, B, C, D classifications), the defining criteria always involve the number of particles of different sizes per unit volume.

Due to limitations in detection instruments, it has been difficult, if not impossible, to accurately measure the cleanliness of actual production environments for a long time. Therefore, our standards set parameters that can achieve cleanliness in cleanrooms, such as an air exchange rate of 50-60 times per hour for ISO Class 6 (Class 1000) cleanrooms.

With advancements in HVAC and detection technologies in recent years, maintaining cleanliness while meeting specified air exchange rates has become less challenging. The 2022 revision of ISO 14644-4 has already eliminated the requirement for air exchange rates.

Compared to semiconductor fabrication facilities, pharmaceutical cleanrooms have smaller spaces, are more numerous, and have high purification requirements but do not necessarily need to be fully equipped with high-efficiency filters. Therefore, in small-space operating environments, there is ample room for optimization to meet both cleanliness needs and improve energy efficiency.

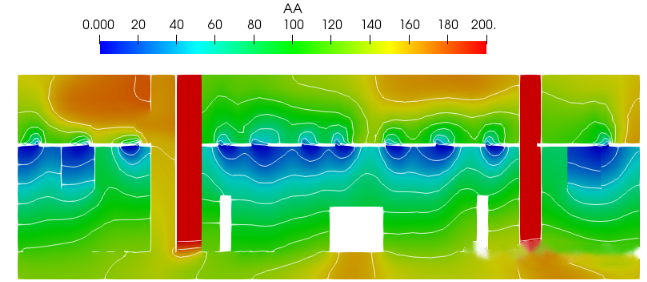

For instance, traditional return air system in pharmaceutical cleanroom areas typically uses return air columns, which are both unsightly and impact spatial layout. In areas with higher cleanliness levels, protruding return air columns can also cause turbulence and vortices in the airflow.

To address this issue, Wiskind Hollow return air unit module can be used to integrate the return air duct into the wall, enabling return air through the wall panel. This can replace the return air columns and 100mm hollow perforated panels in changing rooms, shoe removal buffers, etc., with an average return air volume of 500m³/h, significantly increasing the usable space in the cleanroom. It solves the pain points of traditional return air corridors, such as large floor area, poor sealing, easy core leakage, and difficult construction, while also improving installation efficiency and air outlet connection methods.

Wiskind has successfully upgraded this product to the 3.0 Plus version, improving the processes for key nodes such as return air louvers, filters, and connections between wall panels and ducts. This product has been widely applied in newly constructed pharmaceutical plants of well-known pharmaceutical companies such as Gensciences, Porton Advanced Solutions, Zencore Biologics, and ApicHope Pharmaceutical , and has received unanimous praise.